Slurry Pumps

Slurry is a mixture of solids and liquid, generally water. The particles can be both abrasive & nonabrasive, although abrasive particles are very much common. The purpose to move slurry can be transporting as much solids particles as possible, hydraulically, along with the given liquid. There are many factors to be considered while selecting a slurry pump like; Particle size- Specific gravity of solids, Specific gravity of liquid, Concentration of slurry, Shape of particles etc. Slurry can be further classified in to two types – 1. Non – Settling Slurry & 2. Settling Slurry.

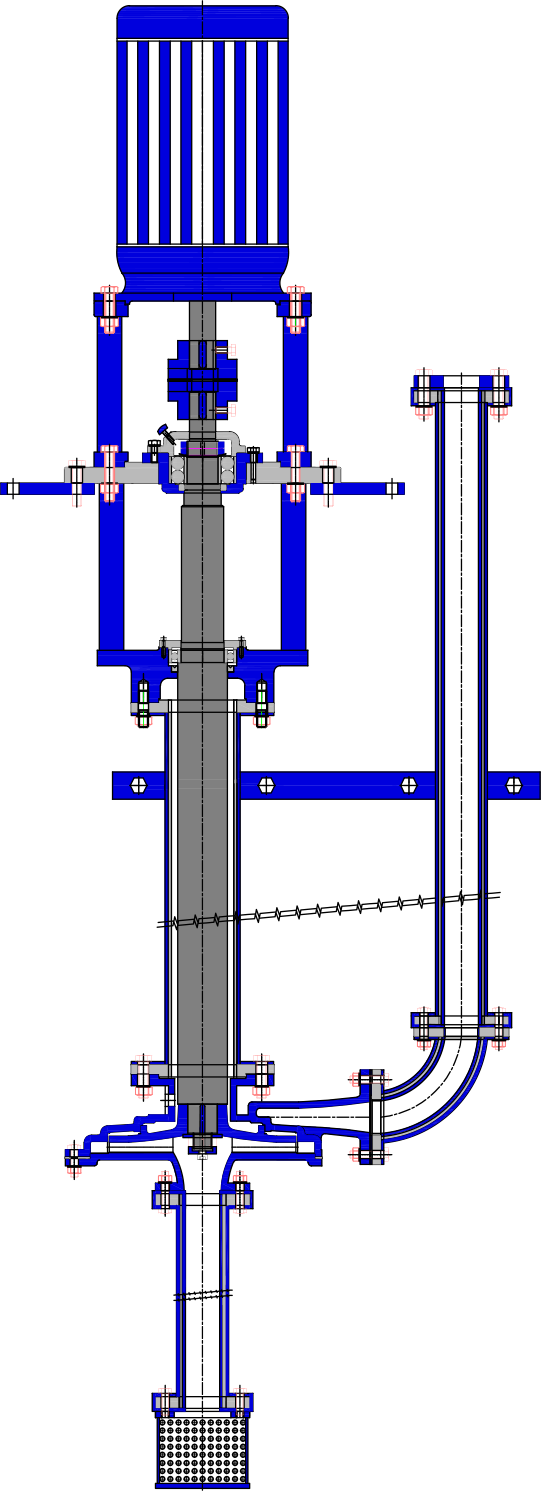

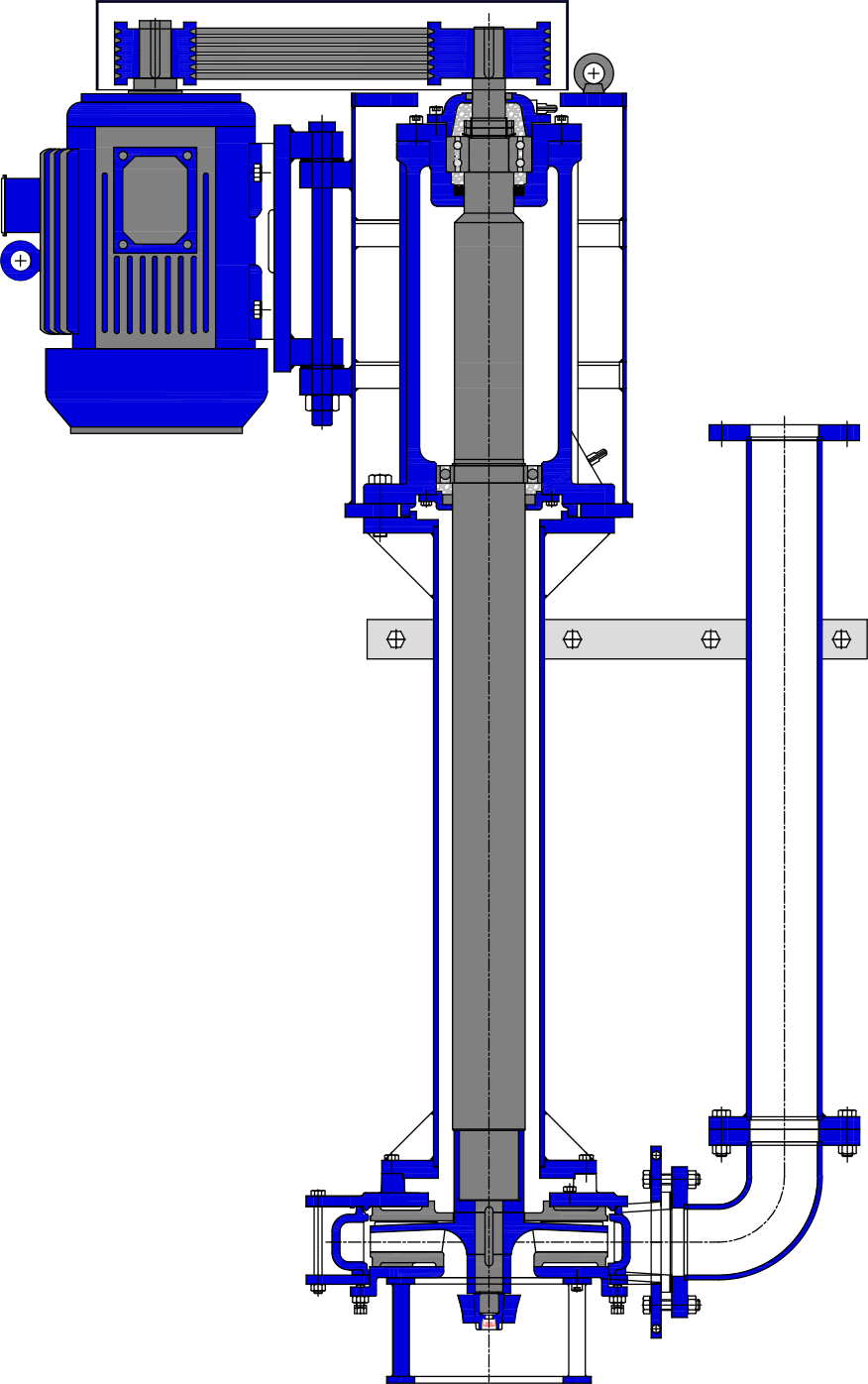

Dredger Series Pump

Features

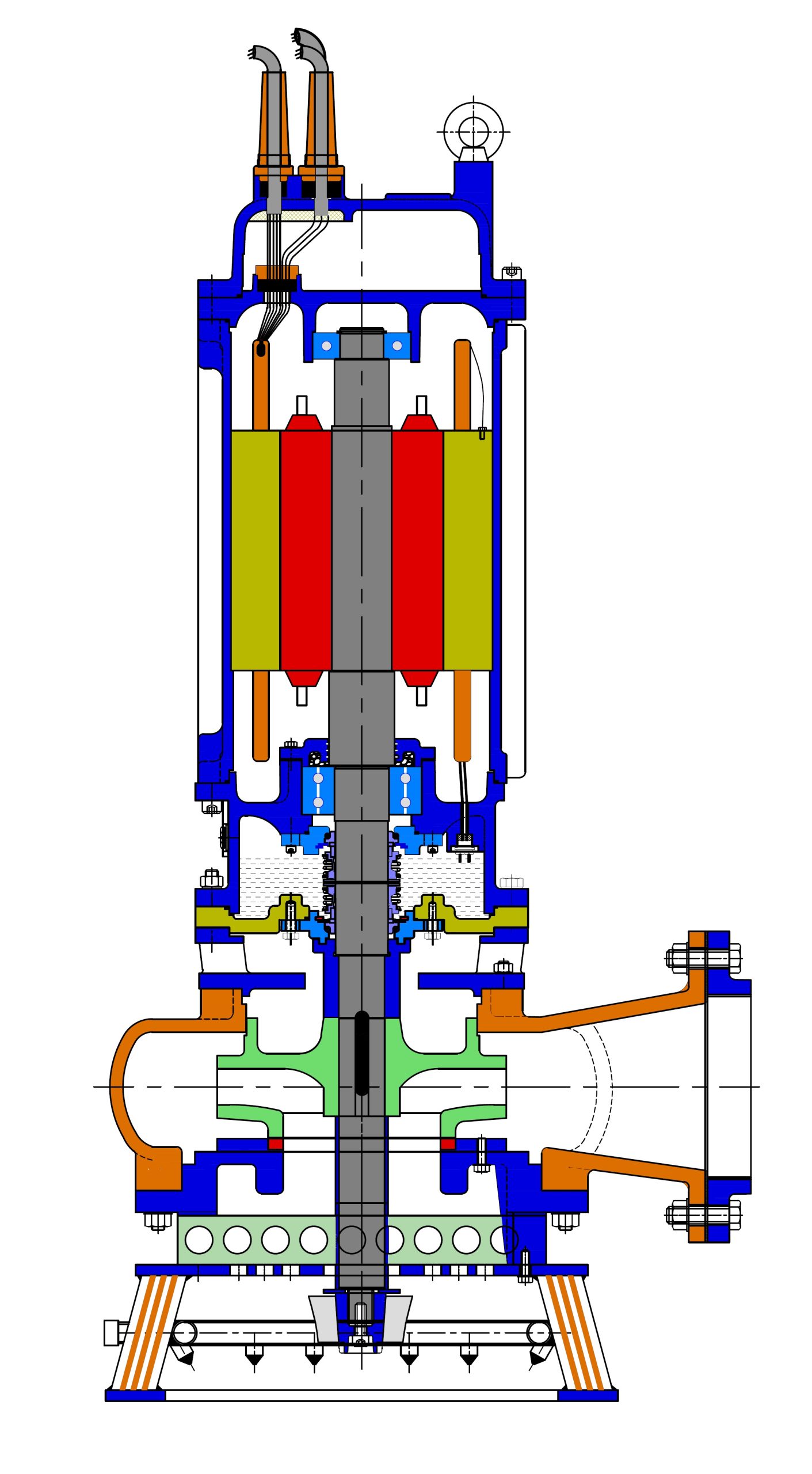

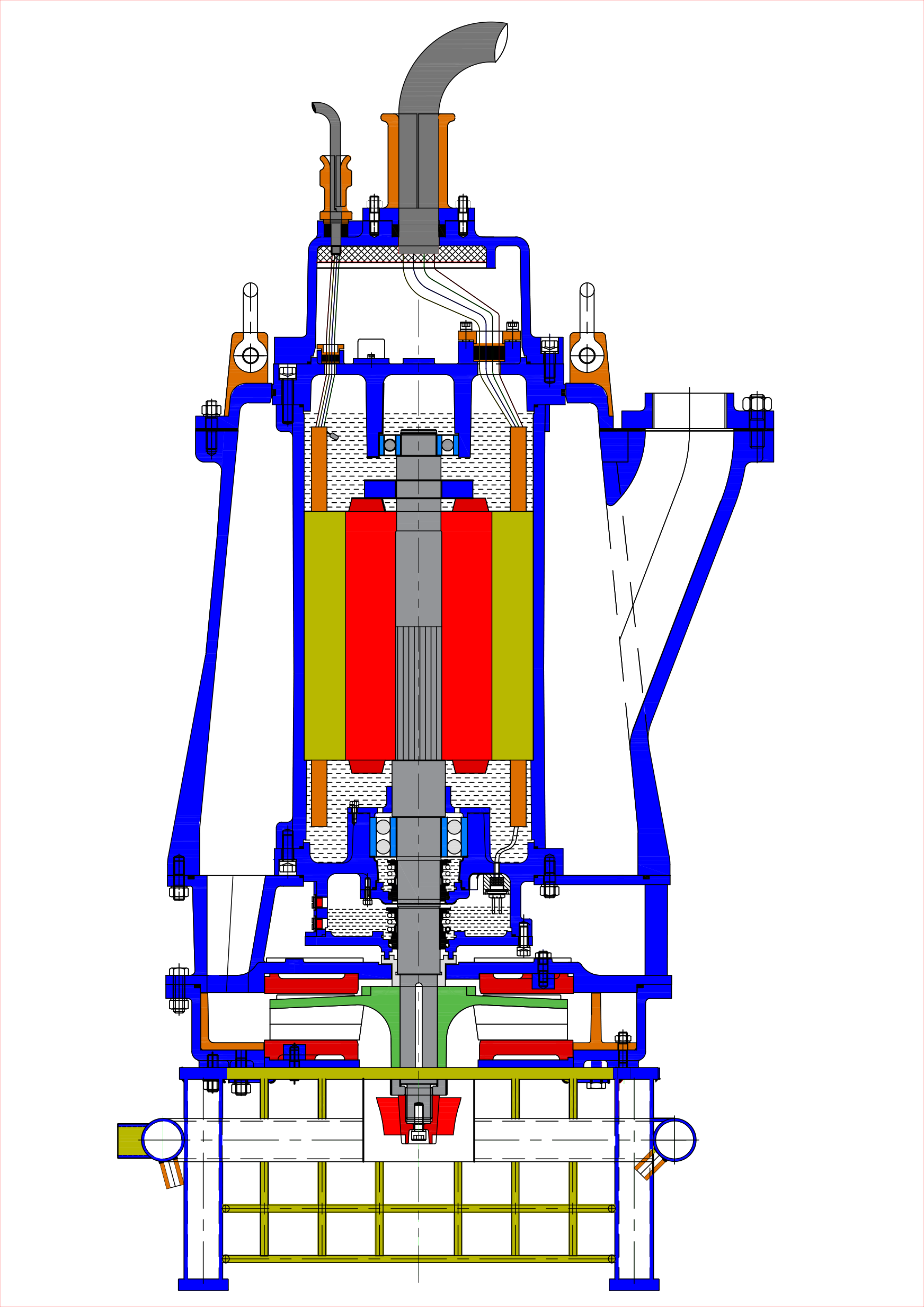

| Impeller – Abrasive resistant Semi open type impeller with hydraulically balanced axial thrust. |

| Shaft– Fully covered heavy duty shaft not exposed to pumpage liquid. |

| Motor – Highly efficient slow speed motors with built-in protection against temperature rise. |

| Wearplate – Abrasive resistant Adjustable and replaceable wear plate to restore clearances for optimum efficiency. |

| Mechanical Seals – Dual mechanical seals Fitted in independent chamber devoid of discharge pressure,ensuring better seal life . Additionaly fitted with seal sensores detect any kind of water ingress. |

| Agitator – Abrasive resistant agitators comes in as a Built-in arrangement. |

| Jetting– In built provision for waterjet arrangement for desettling of slurries. |

| Replacable Wear parts – All wear parts are independantly replacable which bring down running /maintenance coast drastically. |

Applications

- High Abrasive Slurries

- Mill Scale, Iron Ore & Pallet Slurries

- Mineral Ore Processing Units

- Ash & Coal Handling Plants

- Granite & Marble Slurry

- Industrial Waste Removal

- Jack Well / Intake well cleaning

- Removal of Sand deposition at dam galleries & penstock tunnels

- Removal of Sand deposition at dam galleries & penstock tunnels

Dredger Series Pump

| Tech. Specifications* | ||

|---|---|---|

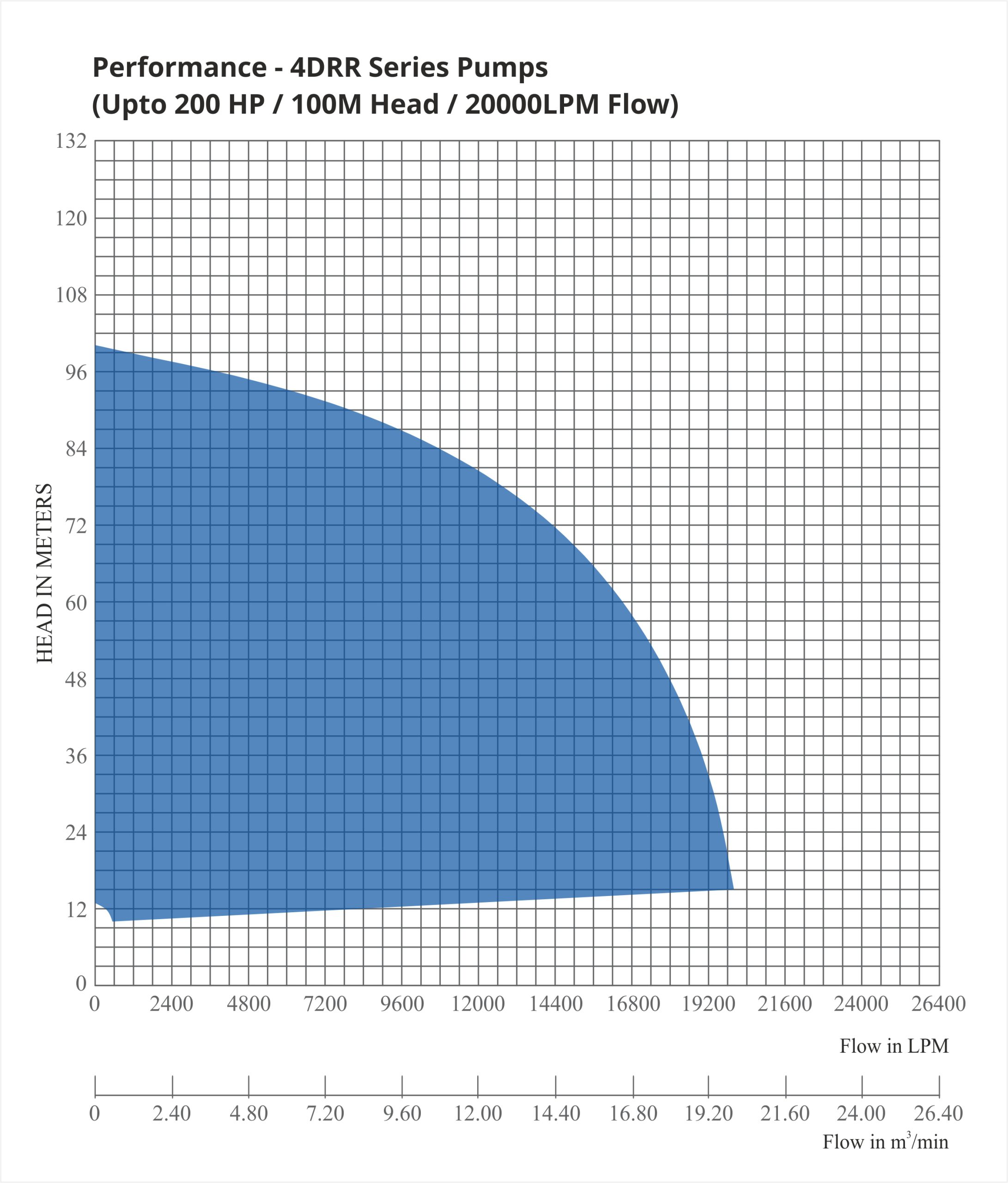

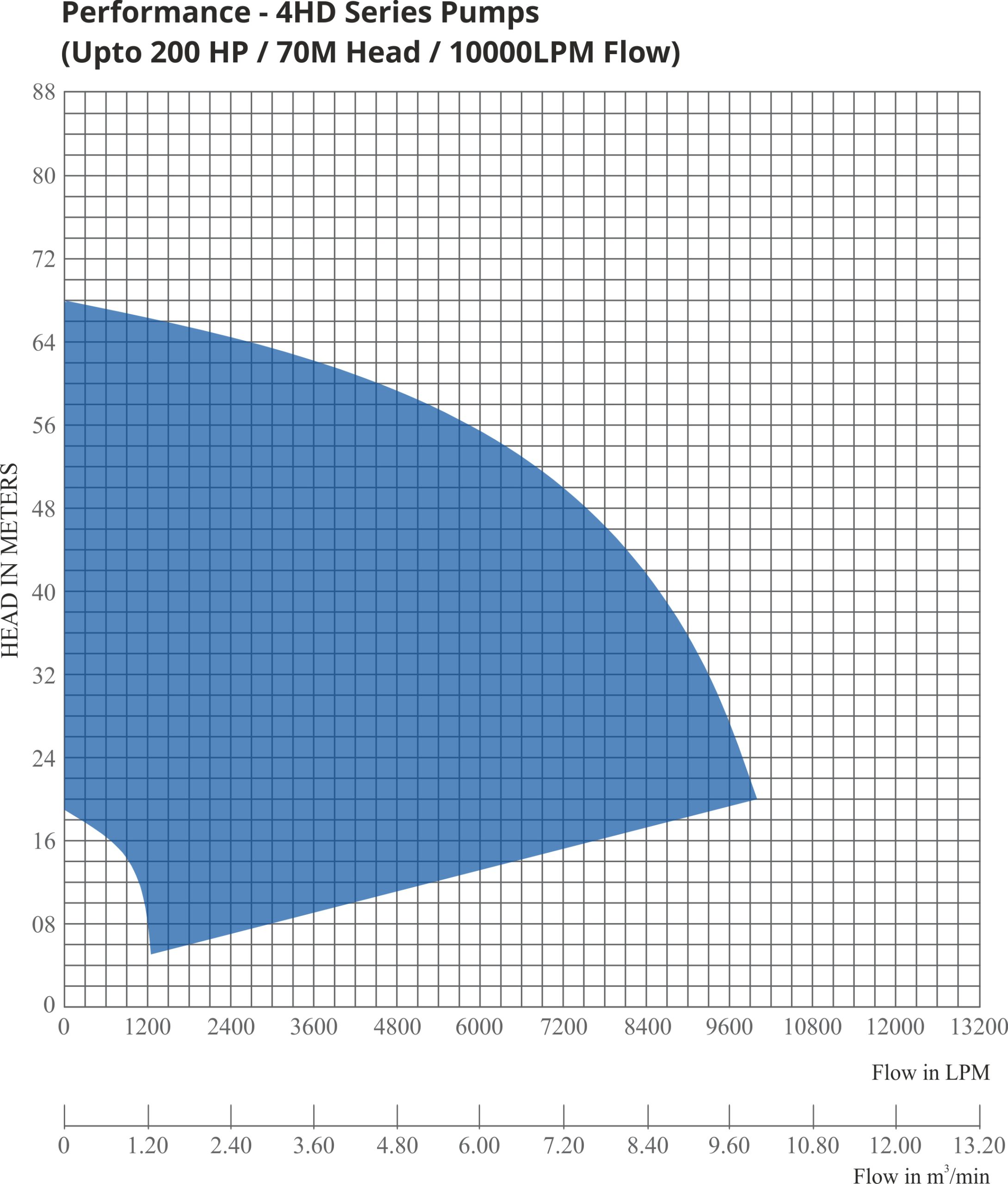

| Rating | : | Up to 200 HP |

| RPM | : | 1450 /960 (nominal) |

| Frequency | : | 50 HZ |

| Supply | : | Three phase- 415 V |

| Starting | : | DOL |

| Motor | : | Wet type / Dry type |

| Process Data | ||

| Liquid temperature | : | Max 40° C |

| Liquid Density | : | 2.8 gm/cc |

| Solid Passage | : | Up to 32 mm |

| Solid Concentration | : | 65% by weight |

| Materials* | ||

| Impeller | : | High Crome, Ni-Hard,hardned SS |

| Shaft | : | SS |

| Difusser | : | Various grades of CI/ AL/ SS |

| Casing | : | Ni-Ci,High Crome, Hi-Hard |

| Wear plate | : | High Crome, Ni-Hard |

| Agitator | : | High Crome, Ni-Hard |

| Mech. Seal | : | Sic v/s Sic, Tc v/s Tc |

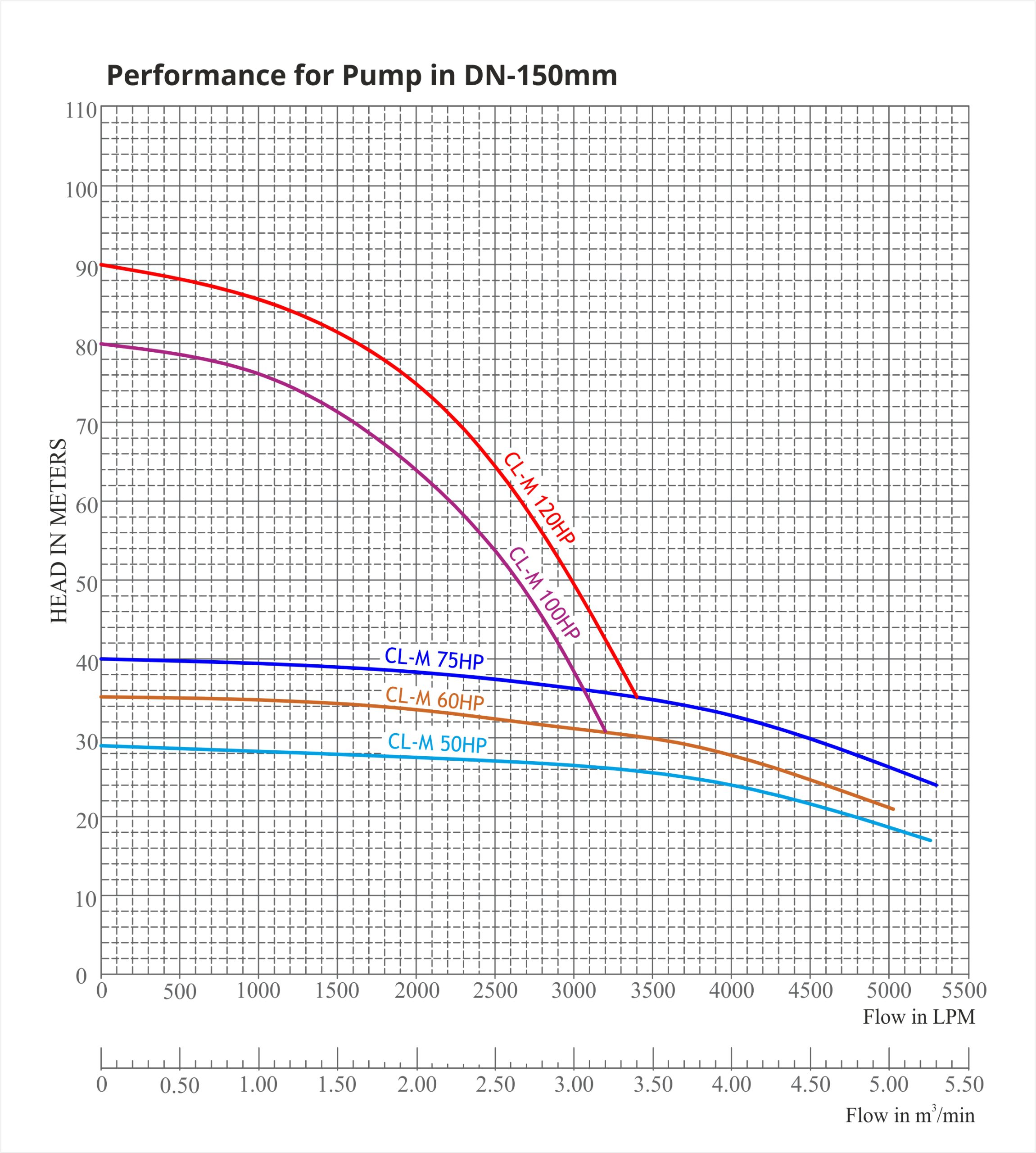

Dredger Series Pump

| Pump Model | HP/KW | RPM | OUTLET / DN SIZE | SOLID PASSAGE | MINIMUM SUBMERGENCE (Approx.) | WIDTH (Approx.) | HEIGHT (Approx.) | Net Weight (In Kg) (Approx.) |

|---|---|---|---|---|---|---|---|---|

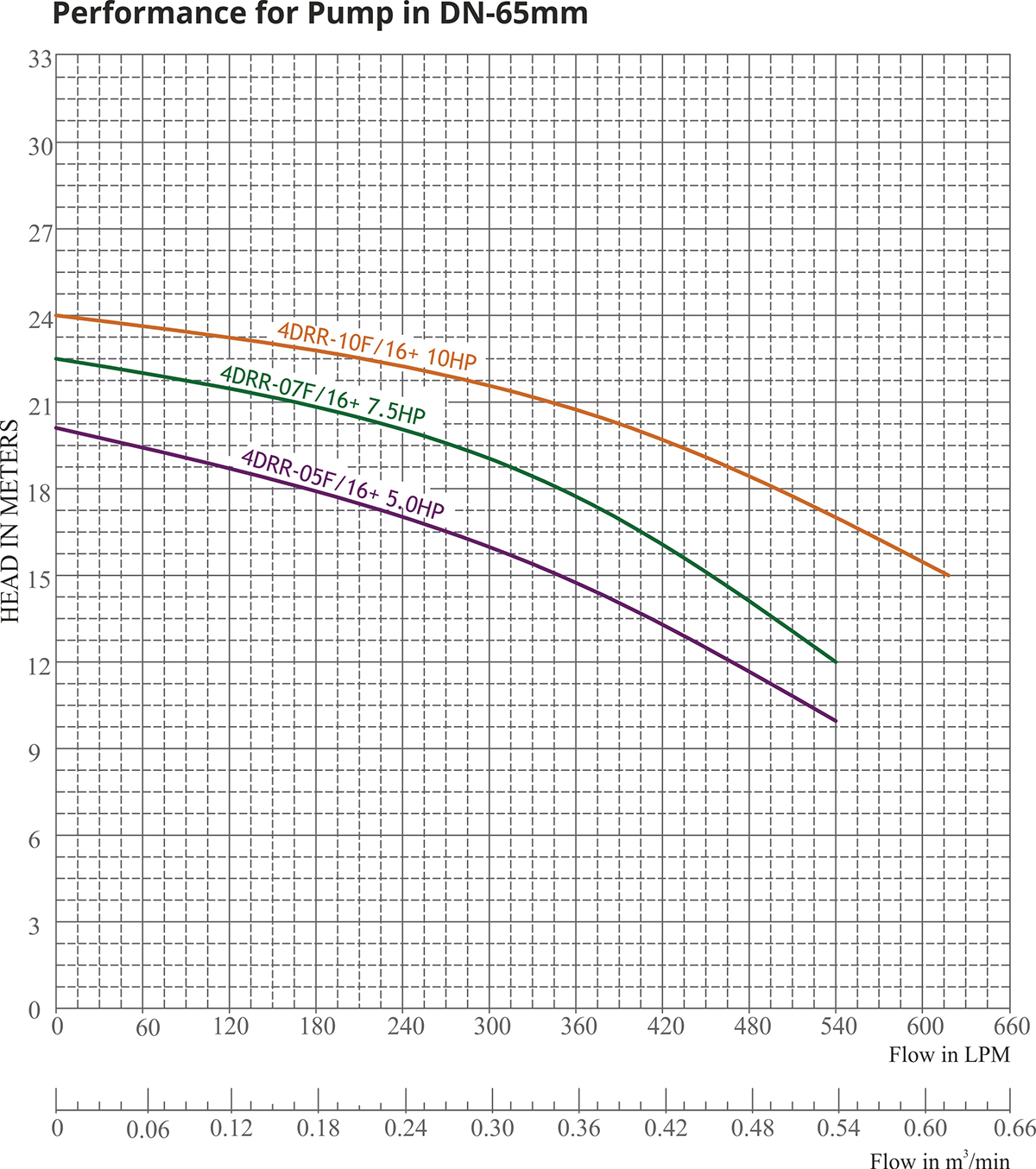

| 4DRR-05F/16+ | 5.0/3.7 | 1450 | 65 | 16 | 740 | 445 | 895 | 150 |

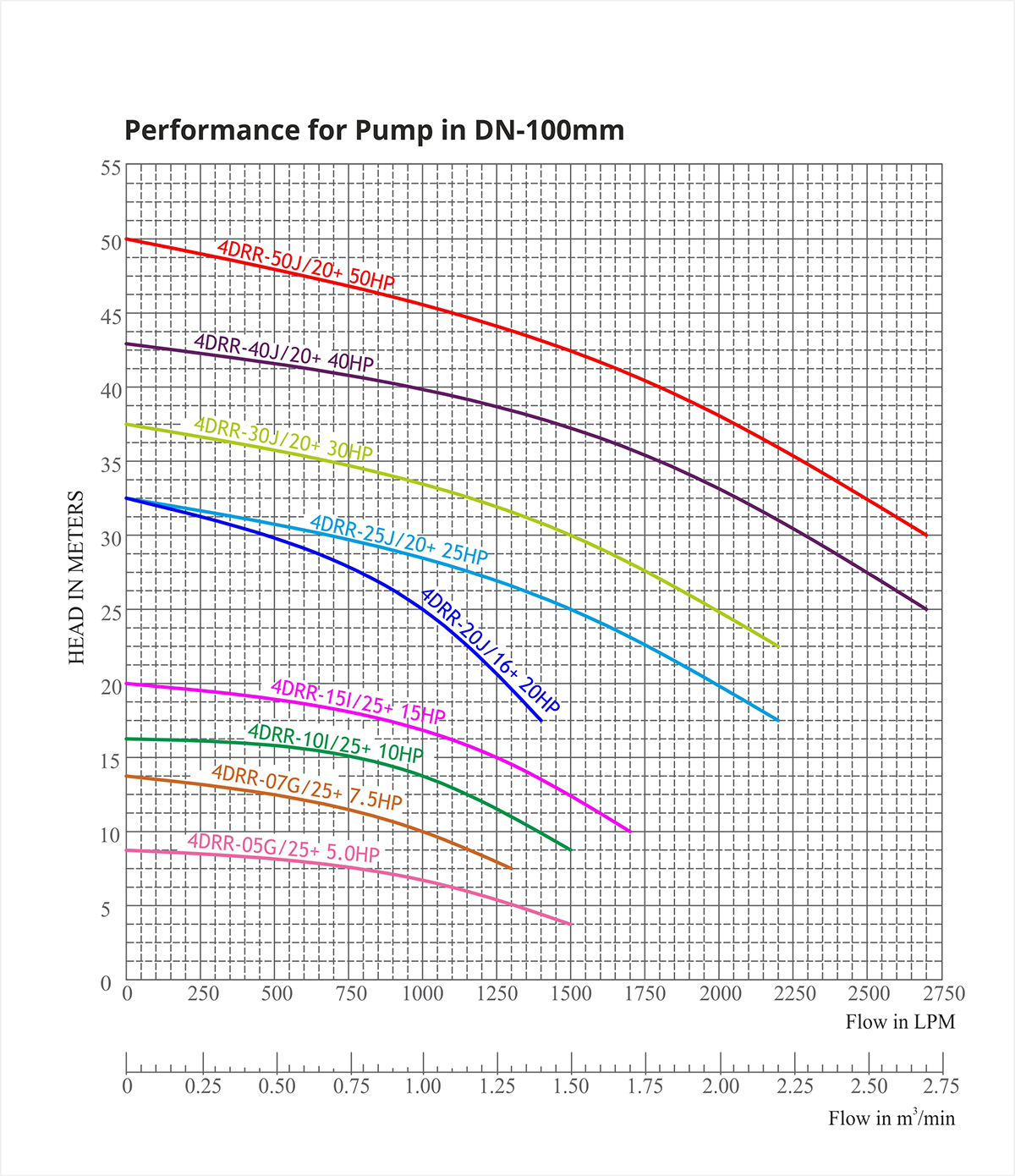

| 4DRR-05G/25+ | 5.0/3.7 | 100 | 25 | 830 | 415 | 985 | 155 | |

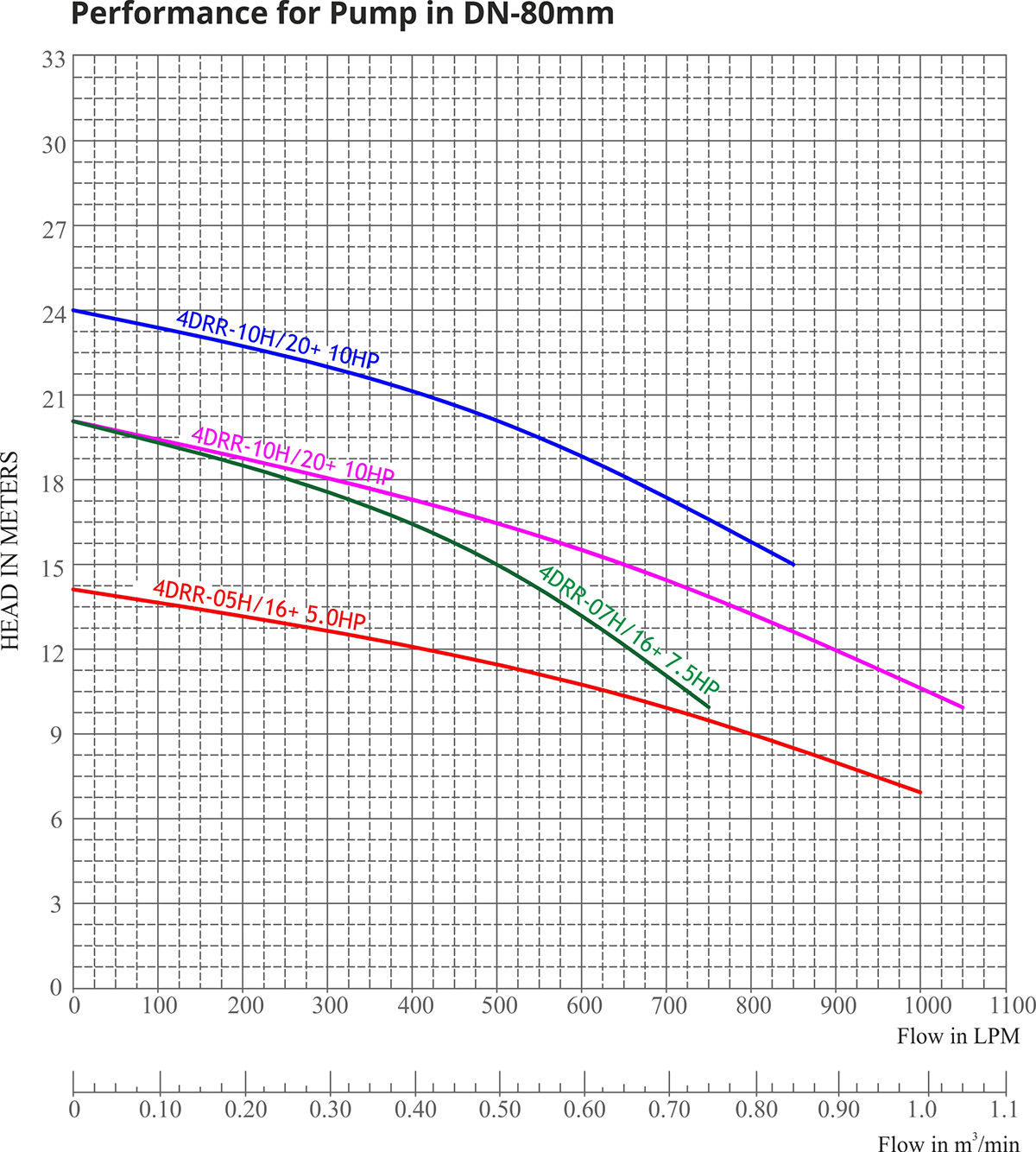

| 4DRR-05H/16+ | 5.0/3.7 | 80 | 16 | 800 | 470 | 950 | 155 | |

| 4DRR-07F/16+ | 7.5/5.5 | 65 | 16 | 725 | 445 | 925 | 205 | |

| 4DRR-07G/25+ | 7.5/5.5 | 100 | 25 | 825 | 415 | 1020 | 205 | |

| 4DRR-07H/16+ | 7.5/5.5 | 80 | 16 | 780 | 465 | 985 | 205 | |

| 4DRR-10F/16+ | 10/7.5 | 65 | 16 | 725 | 445 | 925 | 215 | |

| 4DRR-10H/20+ | 10/7.5 | 80 | 20 | 780 | 465 | 985 | 215 | |

| 4DRR-10I/25+ | 10/7.5 | 100 | 25 | 830 | 475 | 1030 | 230 | |

| 4DRR-15H/16+ | 15/11 | 80 | 16 | 850 | 465 | 1055 | 290 | |

| 4DRR-15I/25+ | 15/11 | 100 | 25 | 890 | 475 | 1095 | 300 | |

| 4DRR-20J/16+ | 20/15 | 100 | 16 | 935 | 650 | 1140 | 370 | |

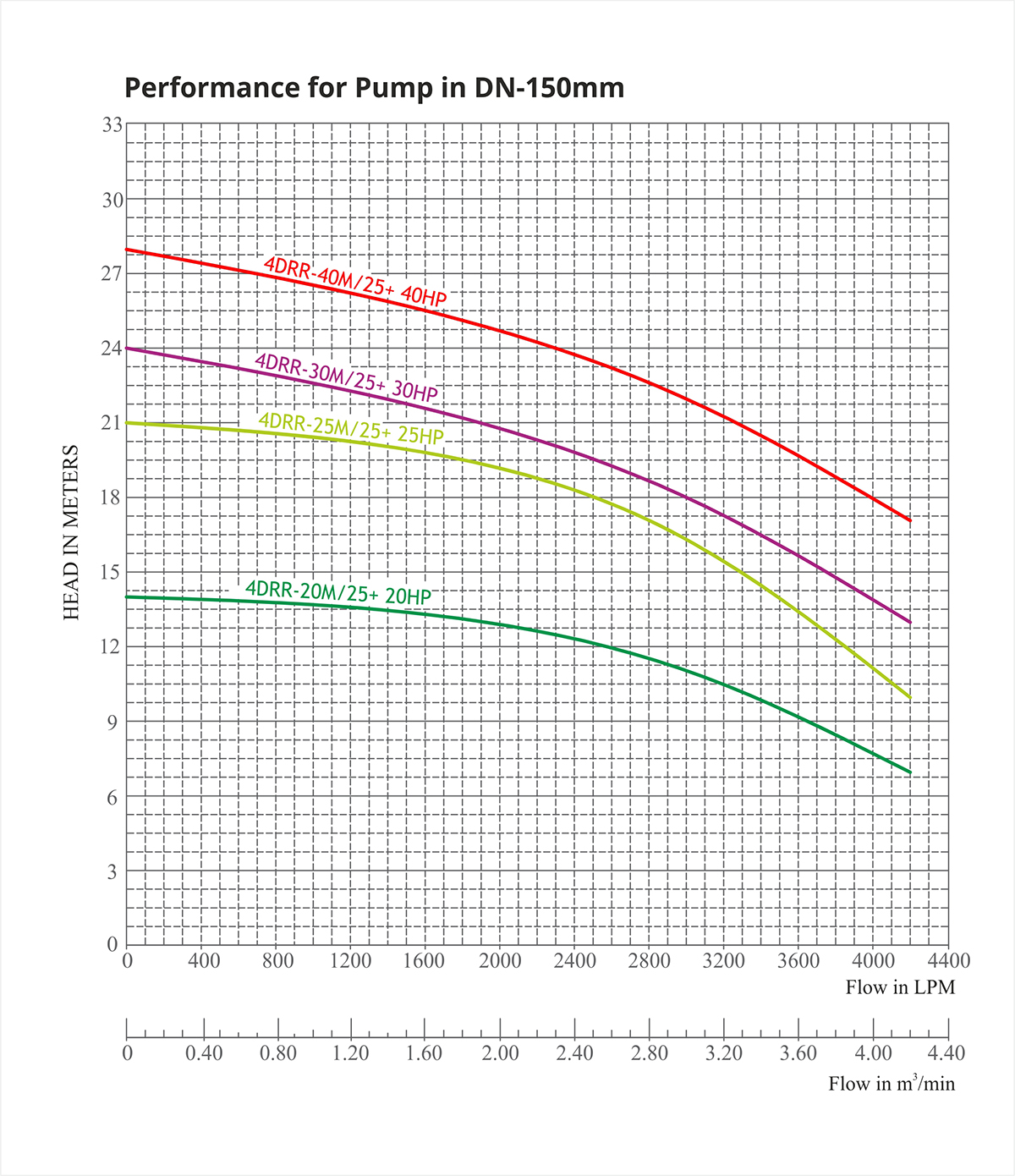

| 4DRR-20M/25+ | 20/15 | 150 | 25 | 965 | 600 | 1175 | 370 | |

| 4DRR-25J/20+ | 25/18.5 | 100 | 20 | 935 | 650 | 1145 | 380 | |

| 4DRR-25M/25+ | 25/18.5 | 150 | 25 | 965 | 600 | 1175 | 380 | |

| 4DRR-30J/20+ | 30/22 | 100 | 20 | 1020 | 650 | 1230 | 400 | |

| 4DRR-30M/25+ | 30/22 | 150 | 25 | 1050 | 600 | 1260 | 400 | |

| 4DRR-40J/20+ | 40/30 | 100 | 20 | 1050 | 650 | 1255 | 420 | |

| 4DRR-40M/25+ | 40/30 | 150 | 25 | 1065 | 600 | 1270 | 420 | |

| 4DRR-50J/20+ | 50/37 | 100 | 20 | 1170 | 650 | 1170 | 680 | |

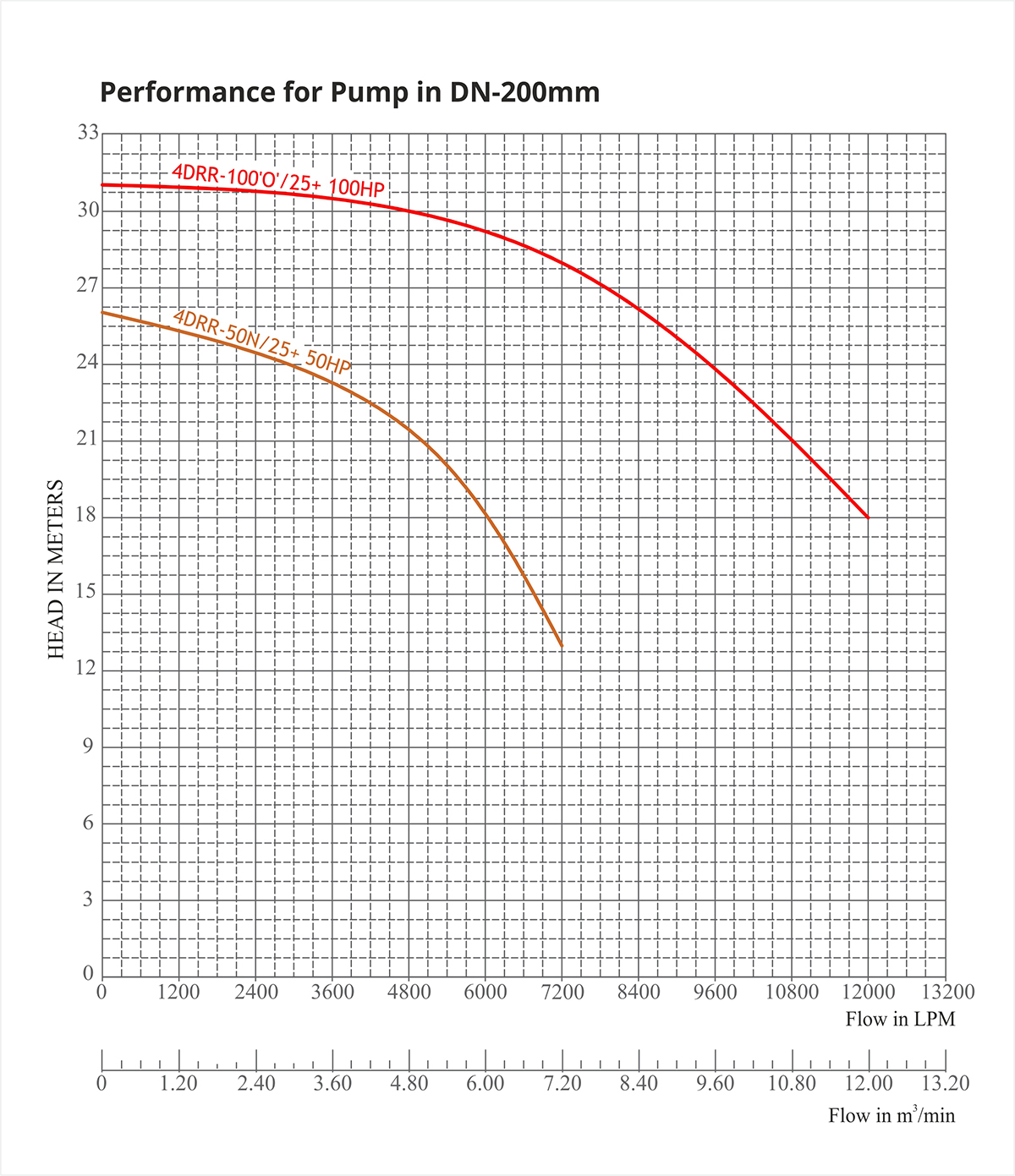

| 4DRR-50N/25+ | 50/37 | 200 | 25 | 1220 | 670 | 1610 | 680 | |

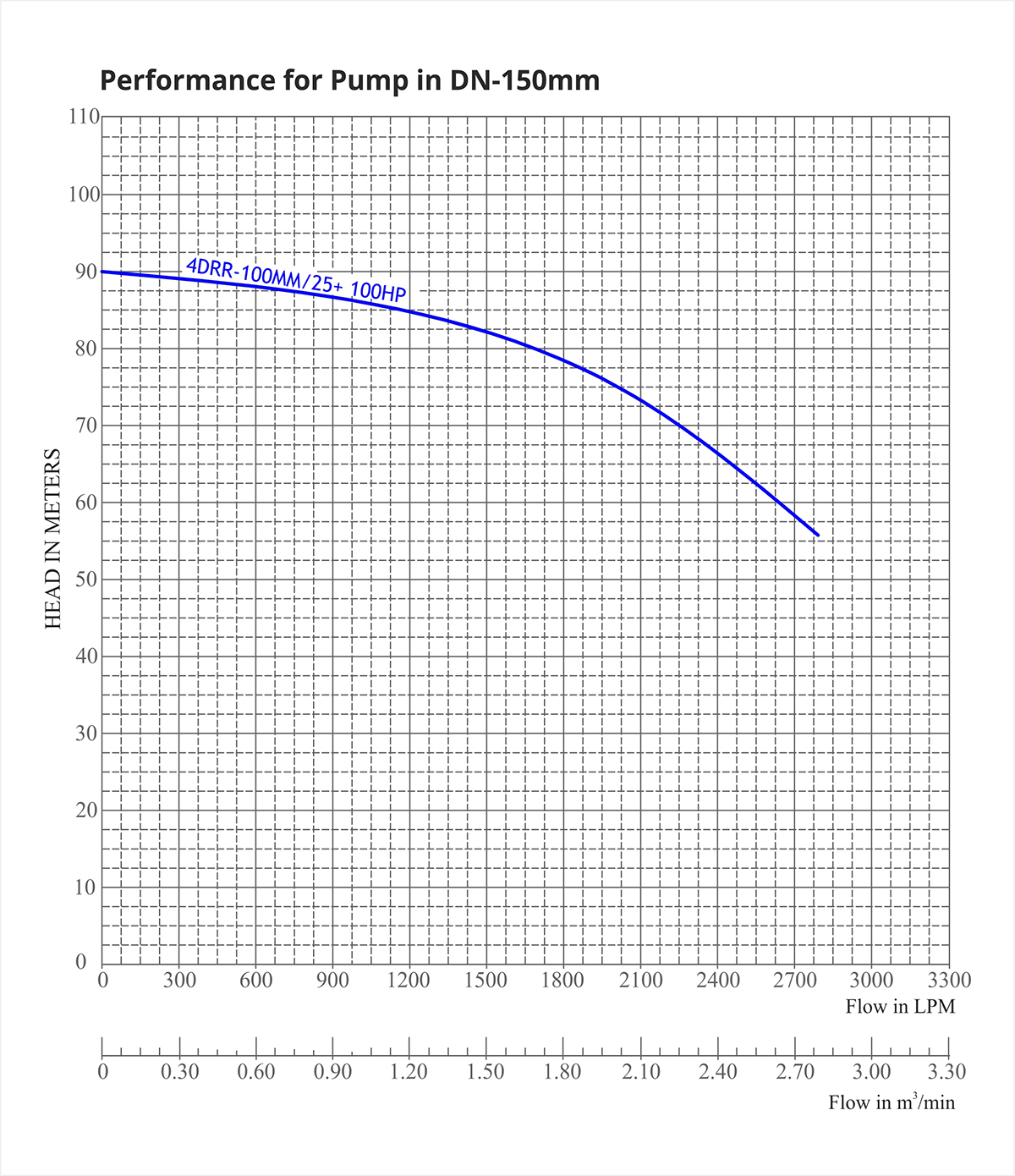

| 4DRR-100’MM’/25+ | 100/75 | 150 | 25 | 1290 | 755 | 1705 | 900 | |

| 4DRR-100’O’/25+ | 100/75 | 200 | 25 | 1430 | 800 | 1850 | 776 | |

| Note: All dimensions are in millimeter (mm). | ||||||||

Dredger Series Pumps

Options

- We offer complete slurry pumping solution for all kind of slurries.

- All slurry pumps are customised to Cater specific needs of users.

- Specialised range of slurry pumps for pumping deep sea slurries.

- Can be offered for pumping high temp. Slurries up to to 90 °C.

- Option of pontoon mounted slurry pumps also available.

- Option of twin volute casing.

- Customised jetting arrangement based on weight and concetration of slurry.

- Customiseble pump stand for maximum slurry pumping

- Pumps can be offered in 60 Hz on request.

Recommendations

- Always flush the pump with clean Water after use.

- In case of maintenance always use genuine spares.

- Use Slurry specific slurry hoses for effective slurry handling.

- Ensure use of proper control panel for proper safety & running of dewatering pumps.

- Always ensure that pump is properly earth.