Clear and Raw Water Pumps

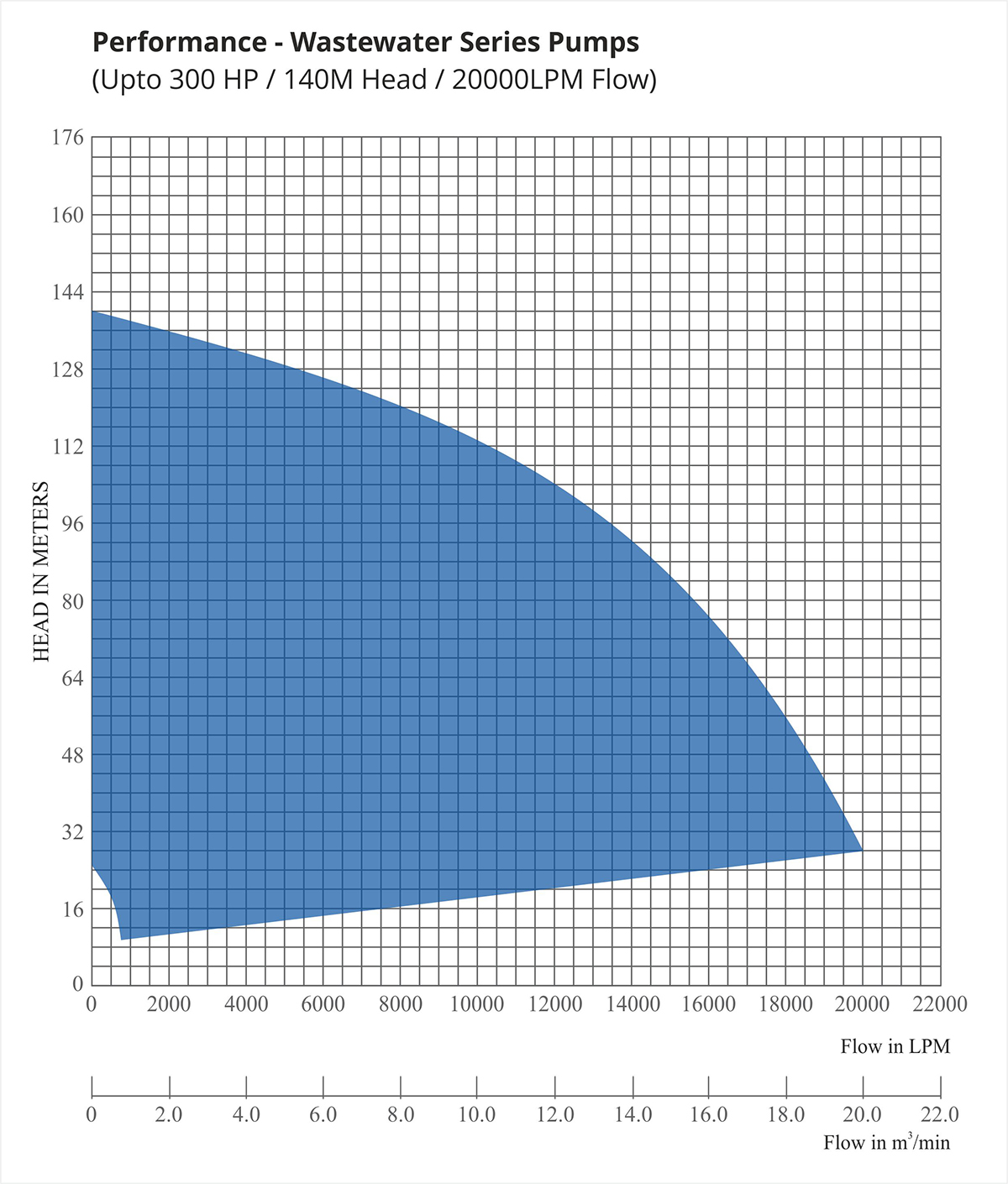

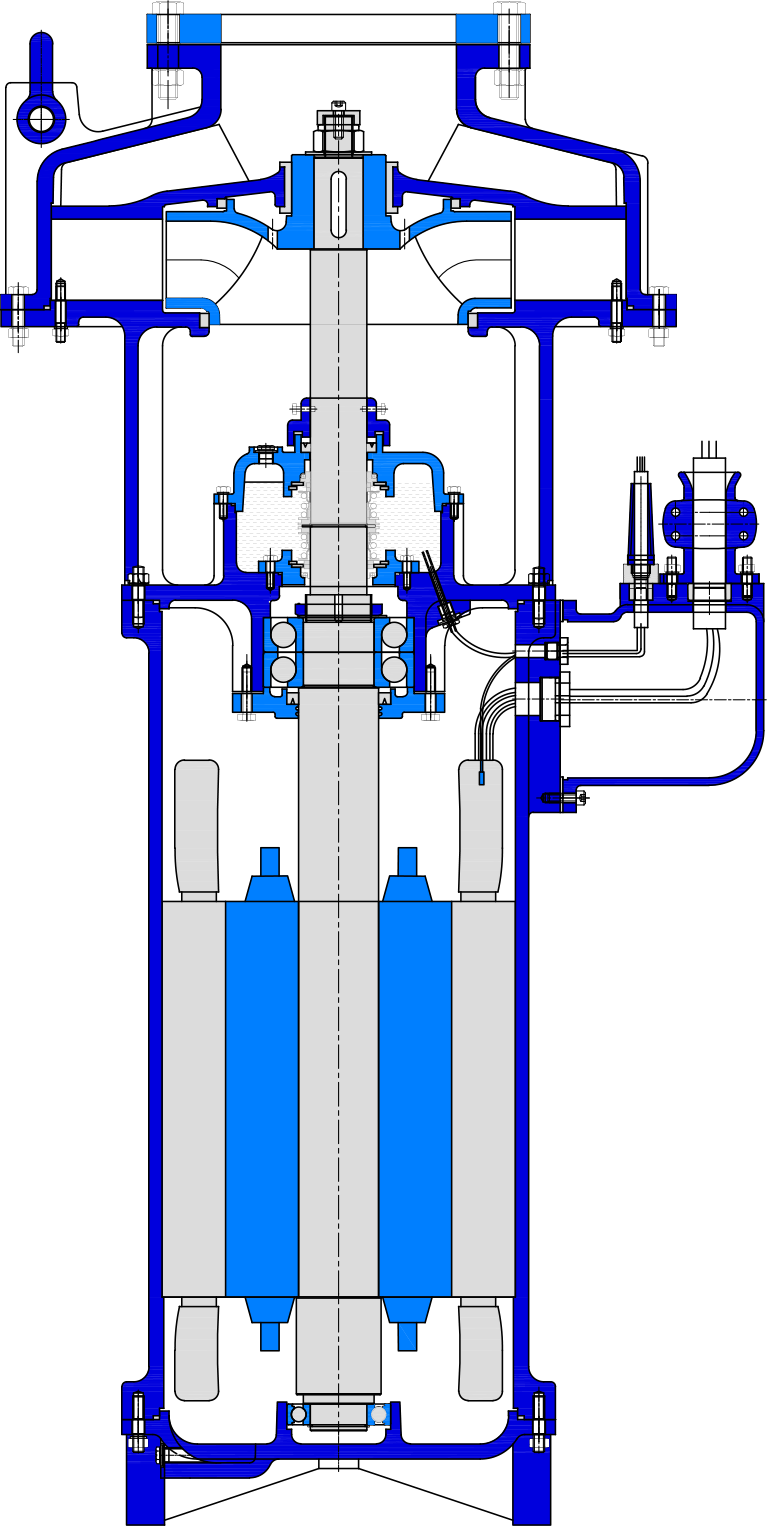

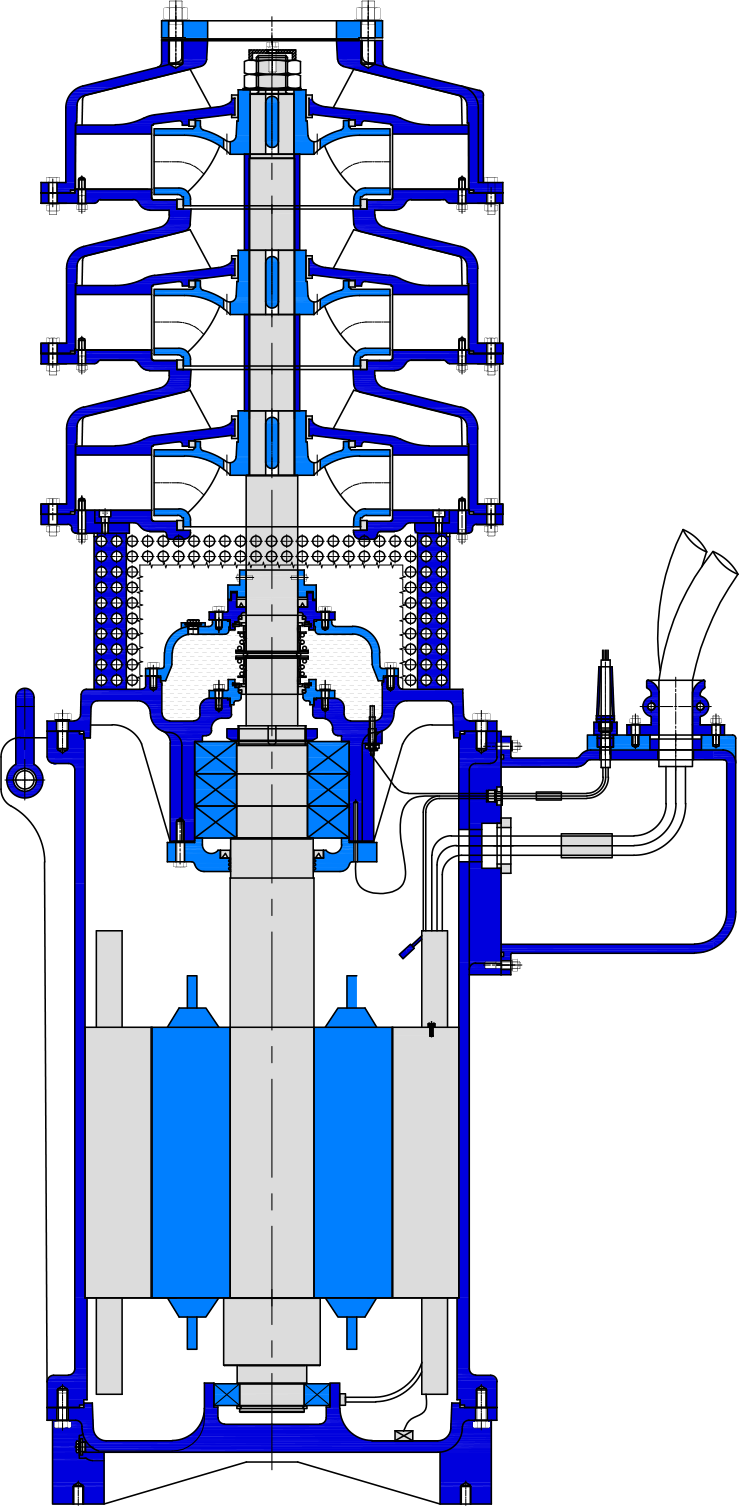

Range of Darling Open Well Submersible Clear Water Pumps consists Of S and M Series Pumps. We are pioneers in this range of pumps and had Indian patent for this product. Our pumps are not only ideal for various agricultural applications but are also very popular for many industrial applications as well. The uniqueness of these submersible clear water pumps is that they are very compact, can be installed in inclined position as well and can offer head up to 140 m in maximum 4 stages.

Darling Pumps has one of the most established ranges of pumps for Raw Water pumping. These pumps are not only useful for pumping out River water, but can very well be modified to pump out Sea water as well. Darling SVT series pumps, with its unique user friendly design are not only very strong, sturdy & compact, but can prove to be very ideal replacement for regular Vertical Turbine Pumps.

Clear and Raw Water Pumps

Features

| Impeller – Highly efficient impeller ensuring more pumping in lesser no. of stages |

| Motor – Highly efficient dry motor with built -in protection against temperature rise.motor capable to withstand wide voltage fluctuations. |

| Shaft – Extra heavy duty SS Shaft to withstand tougher site conditions |

| Mechanical Seals -Pumps are fitted with Mechanical seal in independent chambers, not exposed to pumpage liquid. |

| Bearing– Heavy duty ball bearing used at top and bottom ends to balance adverse load. |

| Sand Guard Arrangemnet – Additional protection for mechanical seal by seal guard. |

| Cable Sealing – Special leak proof cable sealing arrangement,to avoid ingress of water through cable.no need to open motor for changing cable. |

Applications

- Basement Water Dewatering

- Storm Water Dewatering

- Pumping heavily contaminated water with Sand gravel and sludge at various construction sites.

- Sea Water Pumping

- Industrial Water Dewatering

- Dam Sites & Deep Excavation

- Micro Tunneling Projects

- Underground Civil Projects

Clear and Raw Water Pumps

| Tech. Specifications* | ||

| Rating | : | Up to 300 HP |

| RPM | : | 2900 / 1450 |

| Frequency | : | 50 HZ |

| Supply | : | Three phase- 415 V |

| Starting | : | DOL / STAR DELTA |

| Motor | : | Wet type / Dry type |

| Process Data | ||

| Liquid temperature | : | Max 40° C |

| Liquid Density | : | Max 1100 kg/m3 |

| Suitable for liquid pH | : | 6 to 8 |

| Strainer Hole Size | : | Up to 6 mm |

| Materials* | ||

| Impeller | : | CA – 15, CF8, CF8M,various grades of Cl |

| Shaft | : | AISI-410, SS-304, SS-316 |

| Diffuser | : | Various grades of CI/ SS |

| Motor Body | : | Various grades of CI/ SS |

| Mech. Seal | Sic v/s Sic, Tc v/s Tc | |

Clear and Raw Water Pumps

| Pump Model | HP/KW | RPM | OUTLET / DN SIZE | MINIMUM SUBMERGENCE (Approx.) | Solid Passage | OUTER DIA (Approx.) | HEIGHT (Approx.) | Net Weight (In Kg) (Approx.) |

|---|---|---|---|---|---|---|---|---|

| Clear & Raw Water Pumps – Single stage | ||||||||

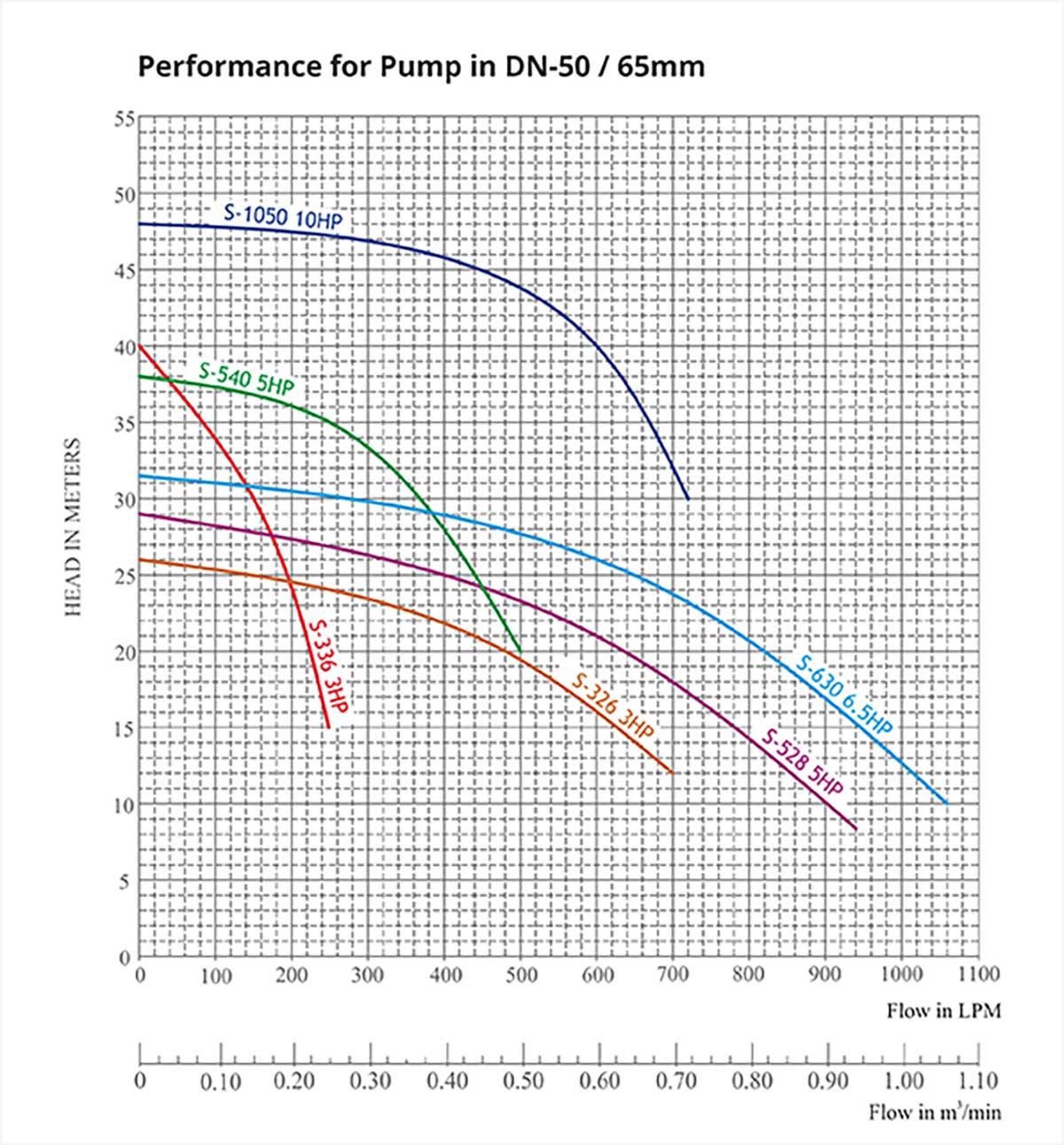

| S-336 | 3.0/2.2 | 2820 | 50 | 315 | NIL | 232 | 430 | 41 |

| S-326 | 3.0/2.2 | 2820 | 65 | 310 | 220 | 435 | 41 | |

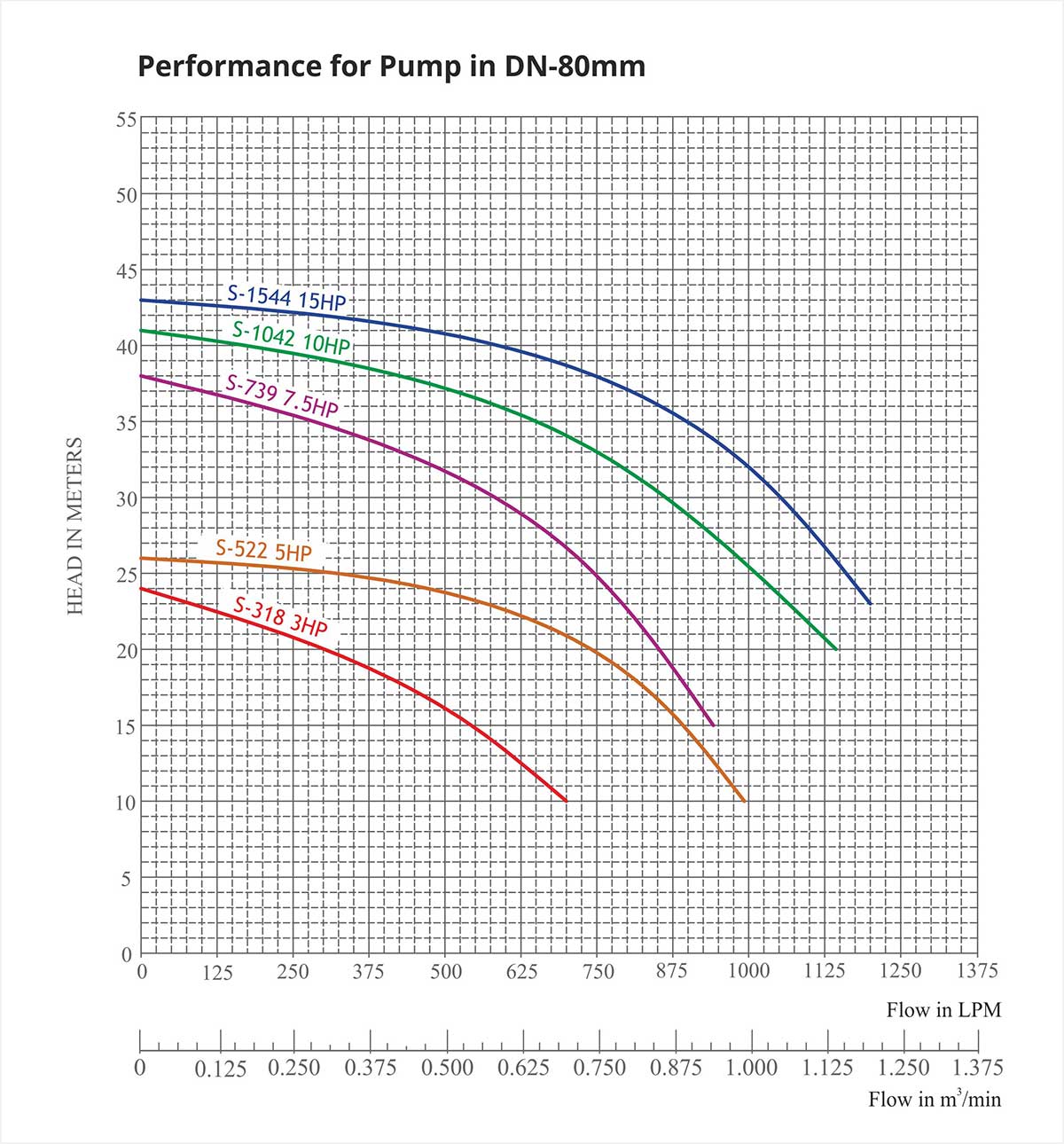

| S-318 | 3.0/2.2 | 2820 | 80 | 310 | 220 | 430 | 41 | |

| S-540 | 5.0/3.7 | 2830 | 65 | 315 | 232 | 430 | 43 | |

| S-528 | 5.0/3.7 | 2830 | 65 | 310 | 220 | 440 | 43 | |

| S-522 | 5.0/3.7 | 2830 | 80 | 310 | 220 | 440 | 43 | |

| S-630 | 6.5/4.8 | 2840 | 65 | 385 | 220 | 515 | 48 | |

| S-739 | 7.5/5.5 | 2850 | 80 | 360 | 261 | 480 | 62 | |

| S-1050 | 10/7.5 | 2850 | 65 | 440 | 261 | 555 | 69 | |

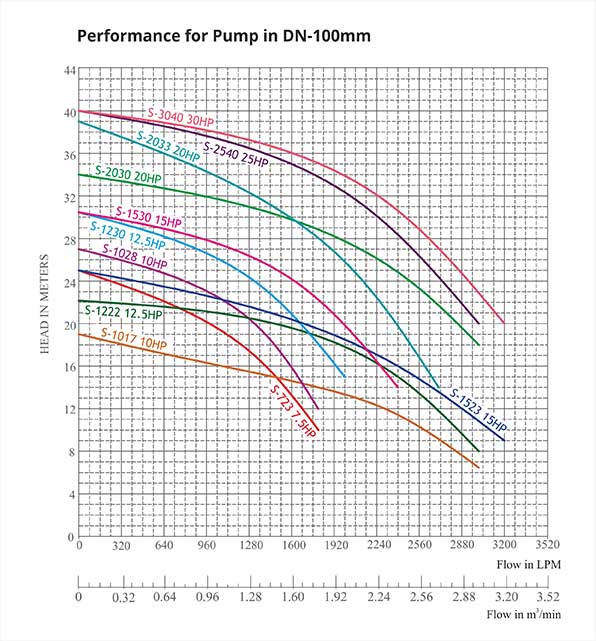

| S-723 | 7.5/5.5 | 2850 | 100 | 405 | 261 | 548 | 70 | |

| S-1042 | 10/7.5 | 2850 | 80 | 440 | 261 | 565 | 75 | |

| S-1028 | 10/7.5 | 2850 | 100 | 440 | 261 | 582 | 80 | |

| S-1017 | 10/7.5 | 2850 | 100 | 440 | 261 | 620 | 80 | |

| S-1230 | 12.5/9.3 | 2860 | 100 | 430 | 300 | 565 | 108 | |

| S-1222 | 12.5/9.3 | 2860 | 100 | 430 | 300 | 605 | 108 | |

| S-1544 | 15/11 | 2870 | 80 | 500 | 300 | 625 | 121 | |

| S-1530 | 15/11 | 2870 | 100 | 500 | 300 | 678 | 125 | |

| S-1523 | 15/11 | 2870 | 100 | 500 | 300 | 678 | 125 | |

| S-2033 | 20/15 | 2880 | 100 | 525 | 300 | 708 | 175 | |

| S-2030 | 20/15 | 2880 | 100 | 525 | 300 | 708 | 175 | |

| S-2540 | 25/18.5 | 2890 | 100 | 595 | 300 | 775 | 180 | |

| S-3040 | 30/22 | 2890 | 100 | 595 | 300 | 775 | 180 | |

| S-3028 | 30/22 | 2890 | 150 | 595 | 300 | 805 | 180 | |

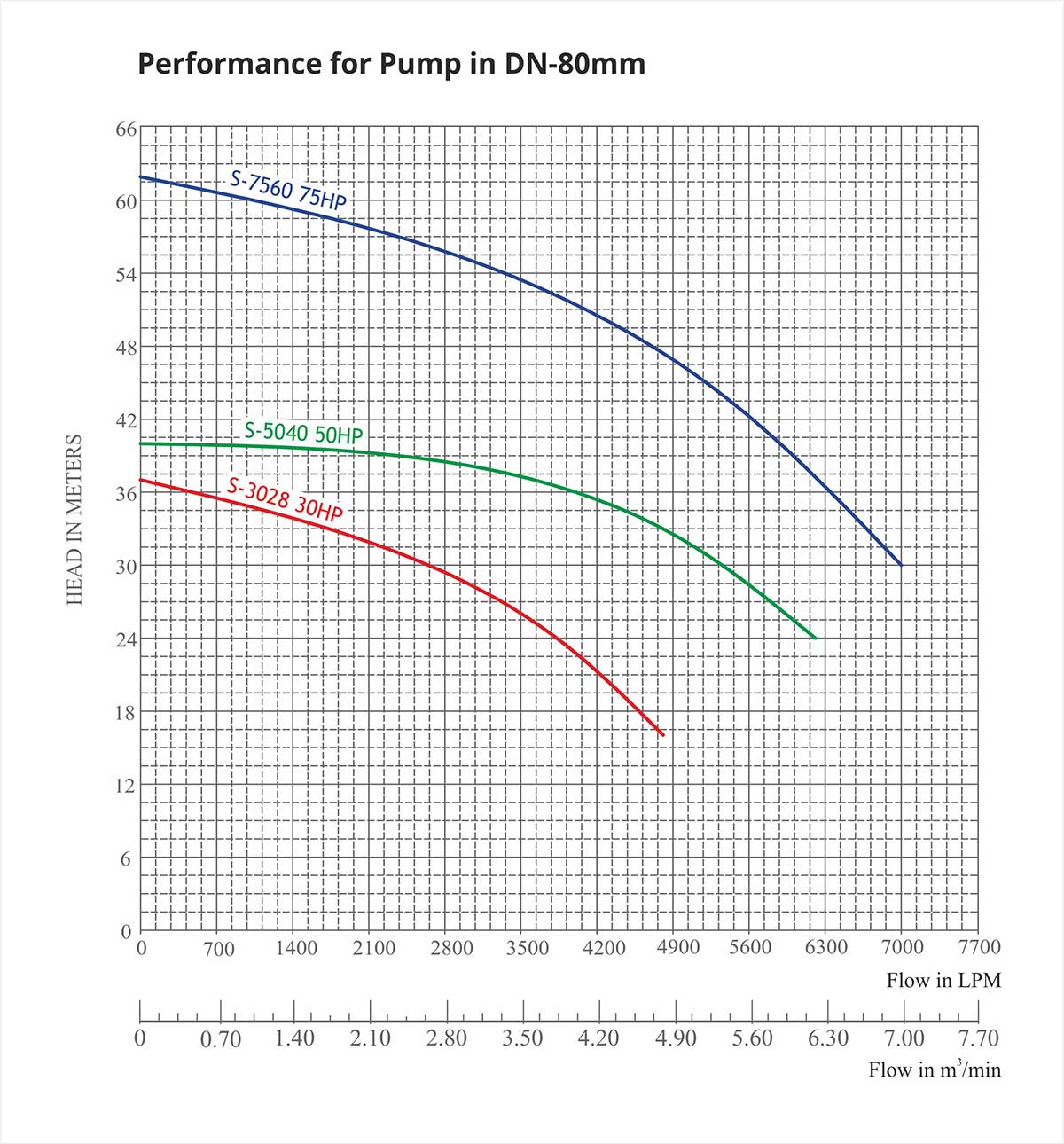

| S-5040 | 50/37 | 2900 | 150 | 940 | 395 | 1135 | 280 | |

| S-7560 | 75/55 | 2900 | 150 | 980 | 395 | 1175 | 375 | |

| Clear & Raw Water Pumps – Multi Stage Pumps | ||||||||

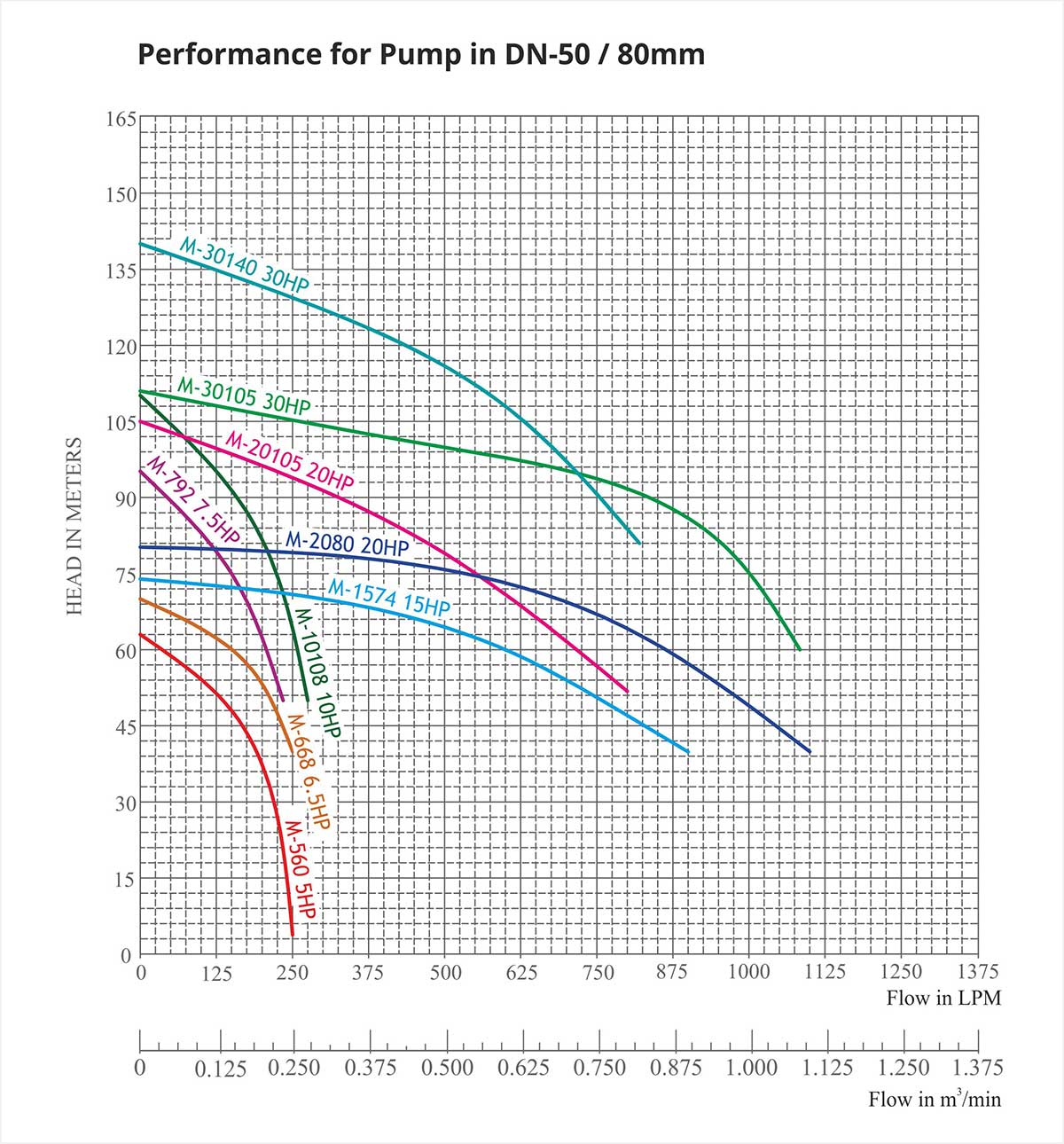

| M-560 | 5.0/3.7 | 2830 | 50 | 315 | NIL | 232 | 480 | 47 |

| M-668 | 6.5/4.8 | 2840 | 50 | 360 | 232 | 525 | 51 | |

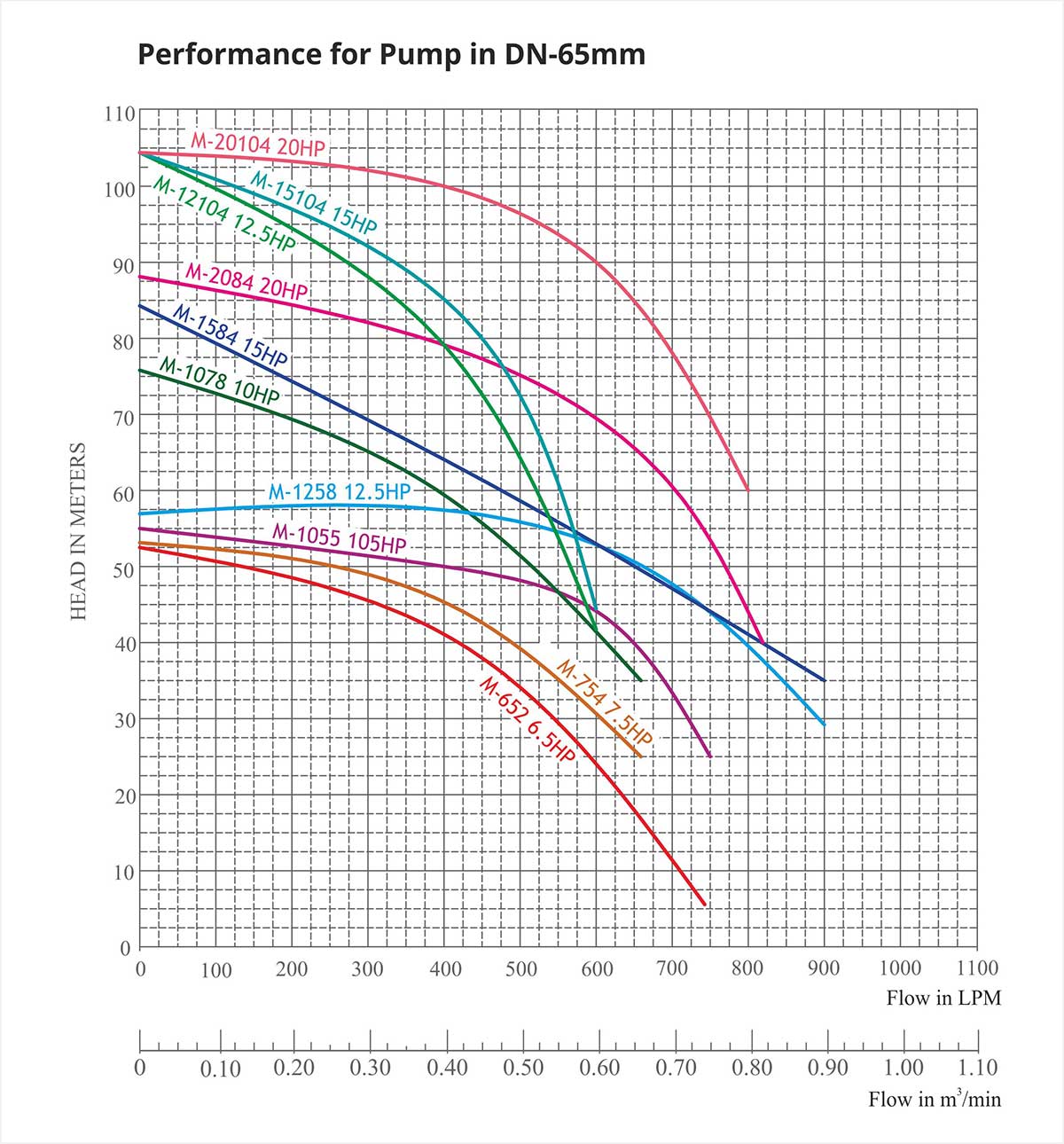

| M-652 | 6.5/4.8 | 2840 | 65 | 355 | 220 | 540 | 51 | |

| M-754 | 7.5/5.5 | 2850 | 65 | 355 | 220 | 540 | 54 | |

| M-1055 | 10/7.5 | 2850 | 65 | 465 | 220 | 655 | 70 | |

| M-792 | 7.5/5.5 | 2850 | 50 | 430 | 232 | 705 | 75 | |

| M-1078 | 10/7.5 | 2850 | 65 | 465 | 220 | 760 | 80 | |

| M-10108 | 10/7.5 | 2850 | 50 | 465 | 232 | 470 | 85 | |

| M-1258 | 12.5/9.3 | 2860 | 65 | 460 | 300 | 654 | 125 | |

| M-1574 | 15/11 | 2870 | 80 | 500 | 300 | 740 | 170 | |

| M-1584 | 15/11 | 2870 | 65 | 500 | 300 | 850 | 175 | |

| M-12104 | 12.5/9.3 | 2860 | 65 | 460 | 300 | 922 | 180 | |

| M-2084 | 20/15 | 2880 | 65 | 525 | 300 | 875 | 180 | |

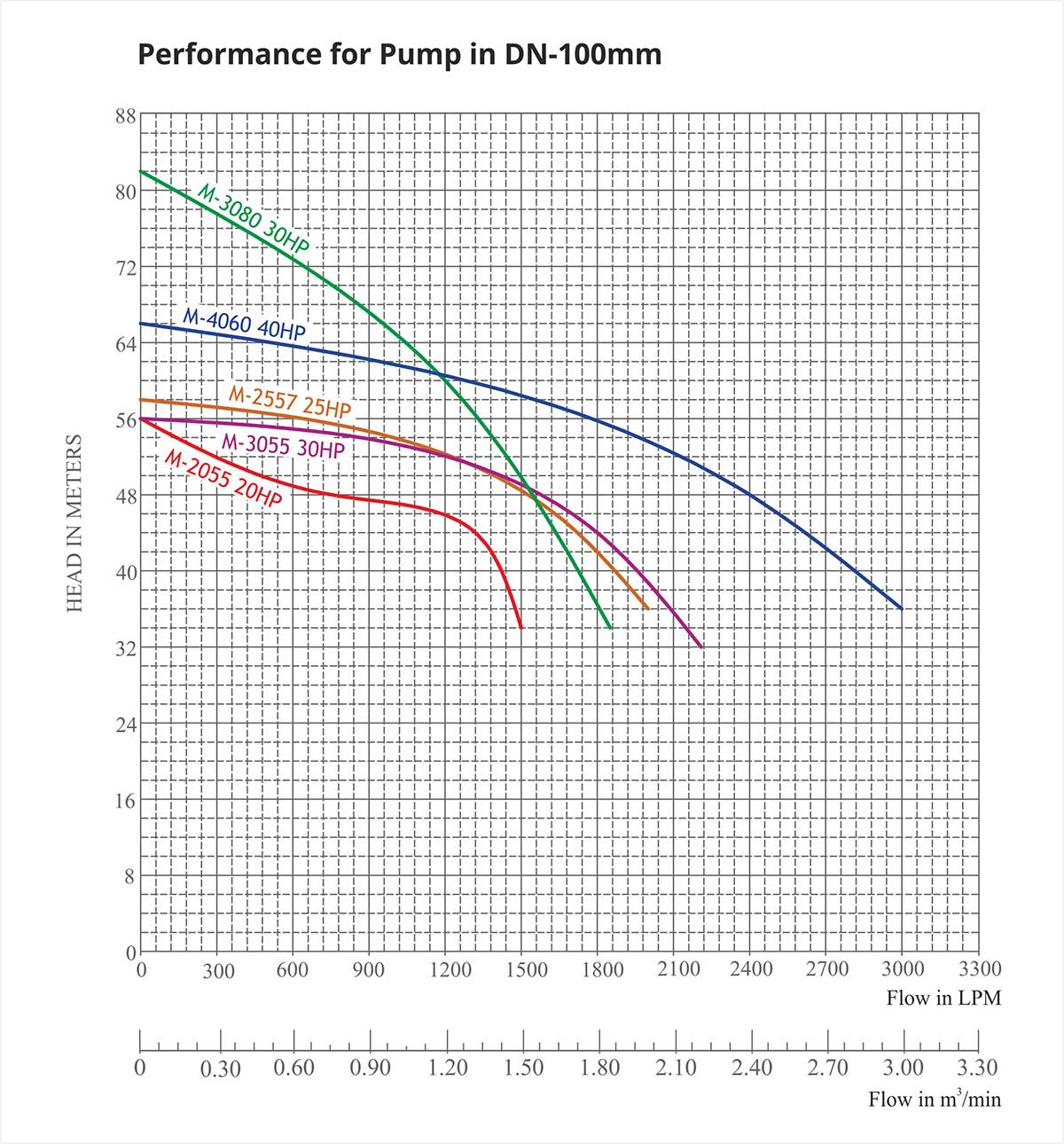

| M-2055 | 20/15 | 2880 | 100 | 525 | 300 | 800 | 180 | |

| M-15104 | 15/11 | 2870 | 65 | 500 | 300 | 962 | 190 | |

| M-2080 | 20/15 | 2880 | 80 | 525 | 300 | 760 | 194 | |

| M-2557 | 25/18.5 | 2890 | 100 | 595 | 300 | 867 | 200 | |

| M-3055 | 30/22 | 2890 | 100 | 595 | 300 | 867 | 200 | |

| M-20105 | 20/15 | 2880 | 80 | 525 | 300 | 875 | 204 | |

| M-3080 | 30/22 | 2890 | 100 | 595 | 300 | 1000 | 225 | |

| M-30105 | 30/22 | 2890 | 80 | 595 | 300 | 955 | 225 | |

| M-20104 | 20/15 | 2880 | 65 | 525 | 300 | 988 | 226 | |

| M-30140 | 30/22 | 2890 | 80 | 595 | 300 | 1065 | 235 | |

| M-4060 | 40/30 | 2900 | 100 | 765 | 358 | 1085 | 270 | |

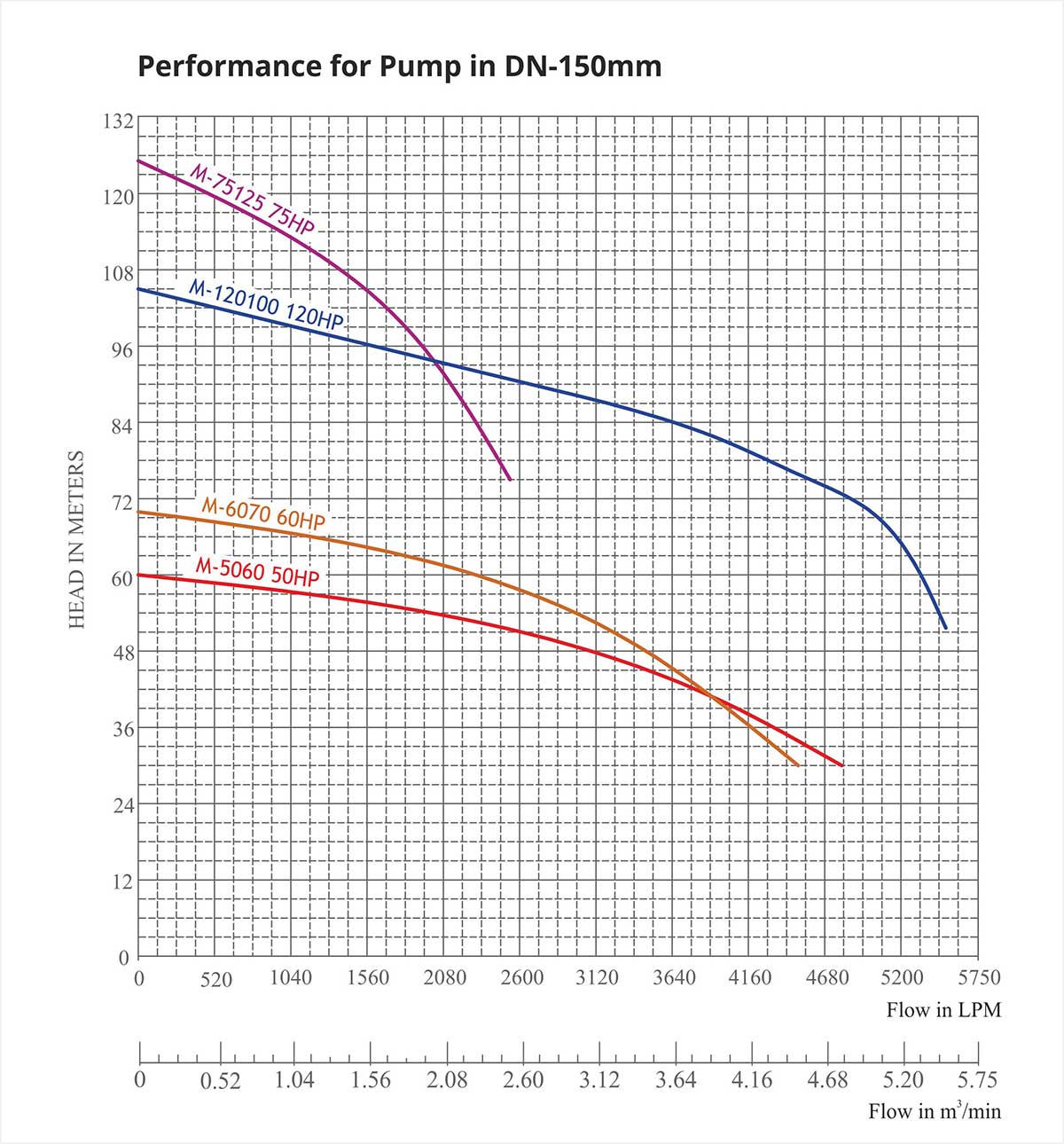

| M-5060 | 50/37 | 2900 | 150 | 1010 | 395 | 1375 | 300 | |

| M-6070 | 60/45 | 2900 | 150 | 1050 | 395 | 1415 | 330 | |

| M-75125 | 75/55 | 2900 | 150 | 930 | 395 | 1295 | 415 | |

| M-120100 | 120/90 | 2900 | 150 | 2000 | 680 | 1550 | 850 | |

| Note: All dimensions are in millimeter (mm). | ||||||||

Clear and Raw Water Pumps

Options

- Option of pump with dry motor as well as oil filled motor.

- Pumps are very ideal for mounting on pantoons & can be offered along with Pantoons arrangement.

- Pumps can be offered for 60 Hz.

- Pumps can be offerred for Sea Water pumping

- Pumps can be offerred for Hot Water pumping

- Variety of MOCs to choose from.

Recommendations

- Always flush the pump with clean water after use.

- In case of maintenance always use genuine spares.

- Ensure use of proper control panel for proper safety & running of dewatering pumps.

- Always ensure that pump is properly earth.