Dewatering Pumps

Dewatering is no more about removing excess water from one place or another, it has lot of other challenges like… dewatering sites are generally open to sky, prone to large amount of mud & debris & are often unmanned. Pumps need to be moved to multiple locations & thus need to be easily portable. Pumps movement, fitment & electrical connections are often done by unskilled labourer & thus pumps are prone to damage during its movement or faulty electrical connections. Many a times due to ignorance, omission or un foreseen emergency pumps are put in to operation directly on main supply without using control panel in between. Due to this, pumps are generally exposed to erratic power supply, whether used on electrical supply or supply through genset. Due to all these uncertainties site engineers have to live with frequent breakdown of pump sets due to dry running, single phasing or mechanical jamming.

Worry no more… Darling Pumps, today has one of the widest range of dewatering pumps, which comes with many unique built-in protections to overcome above challenges…We understand water better, so we handle it better, water of various types & qualities.

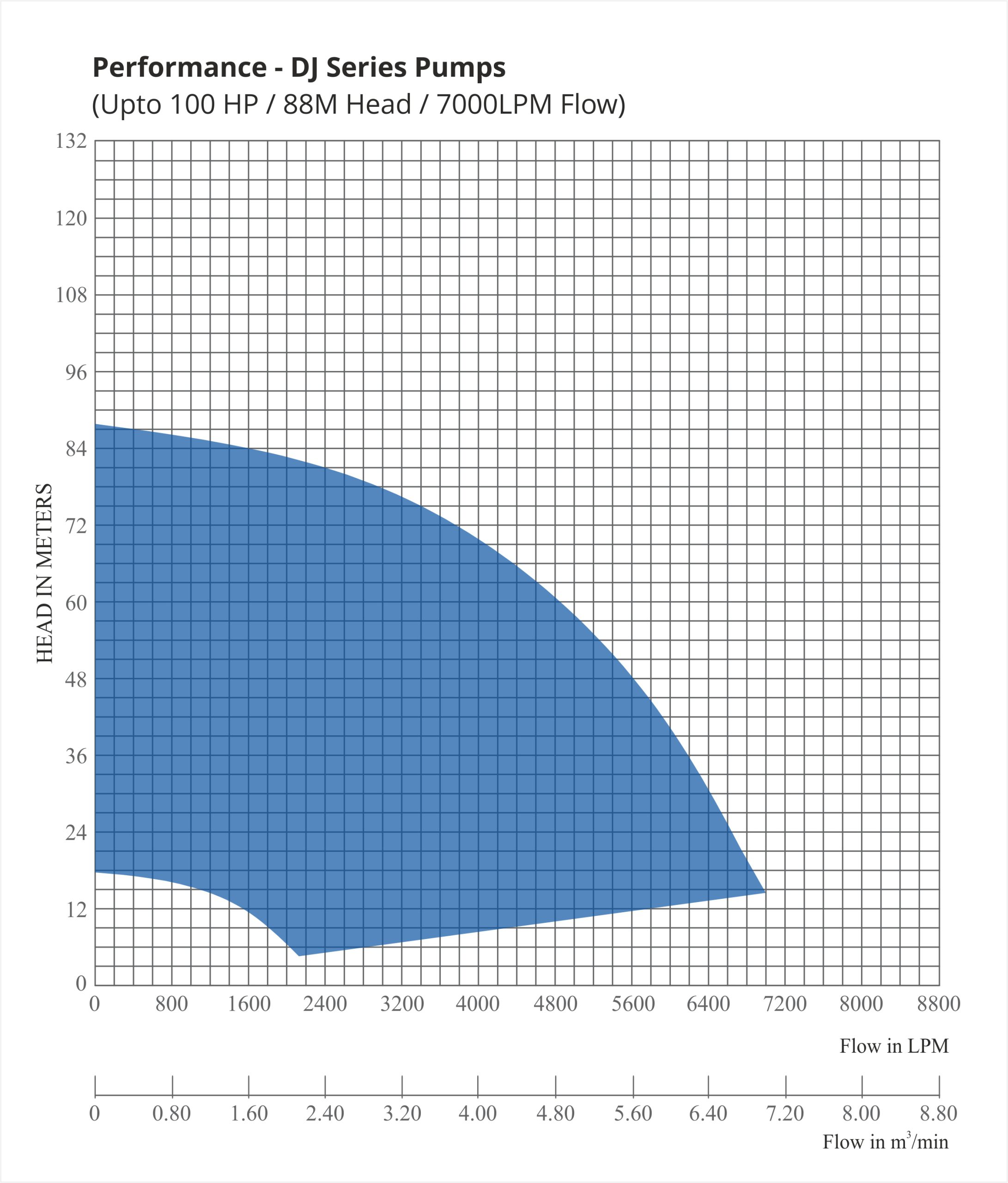

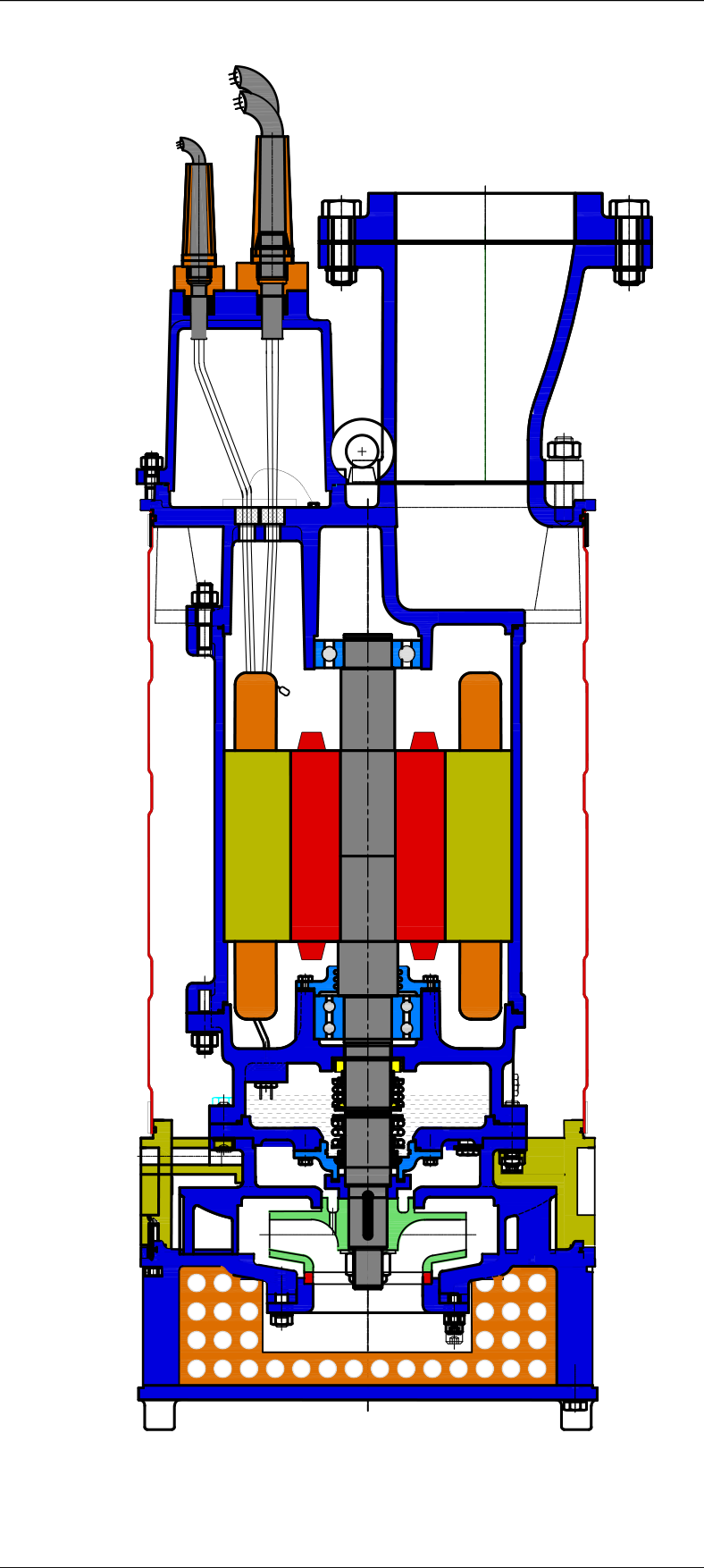

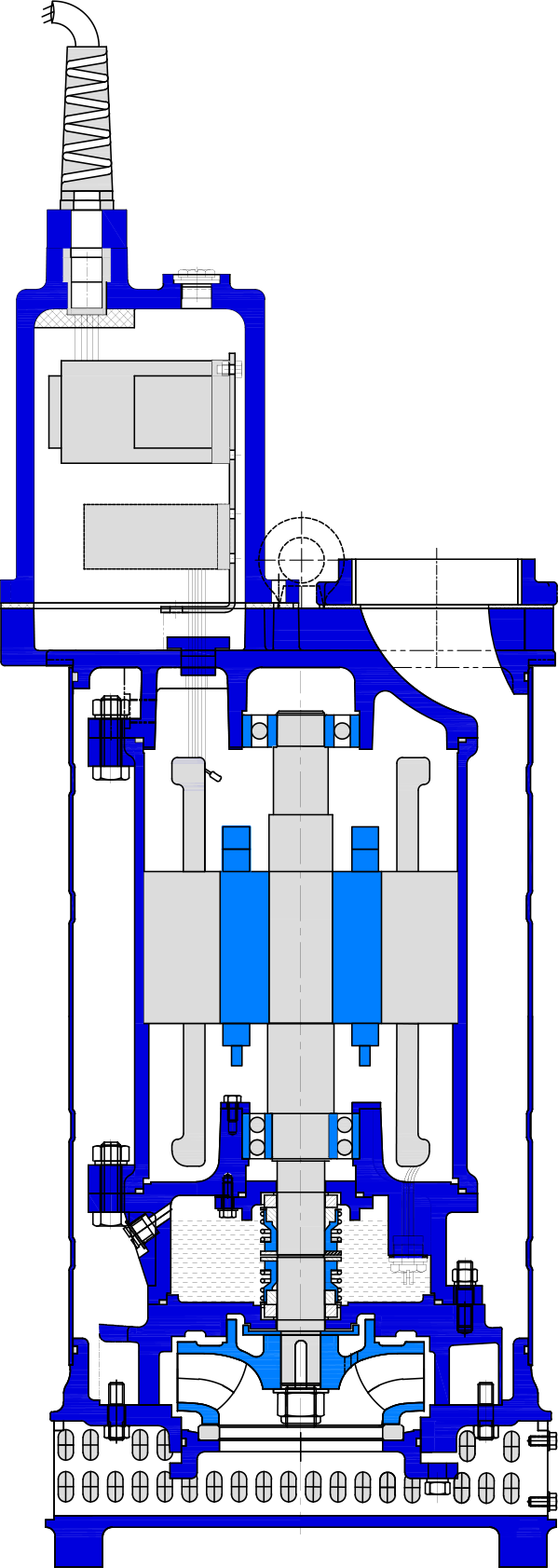

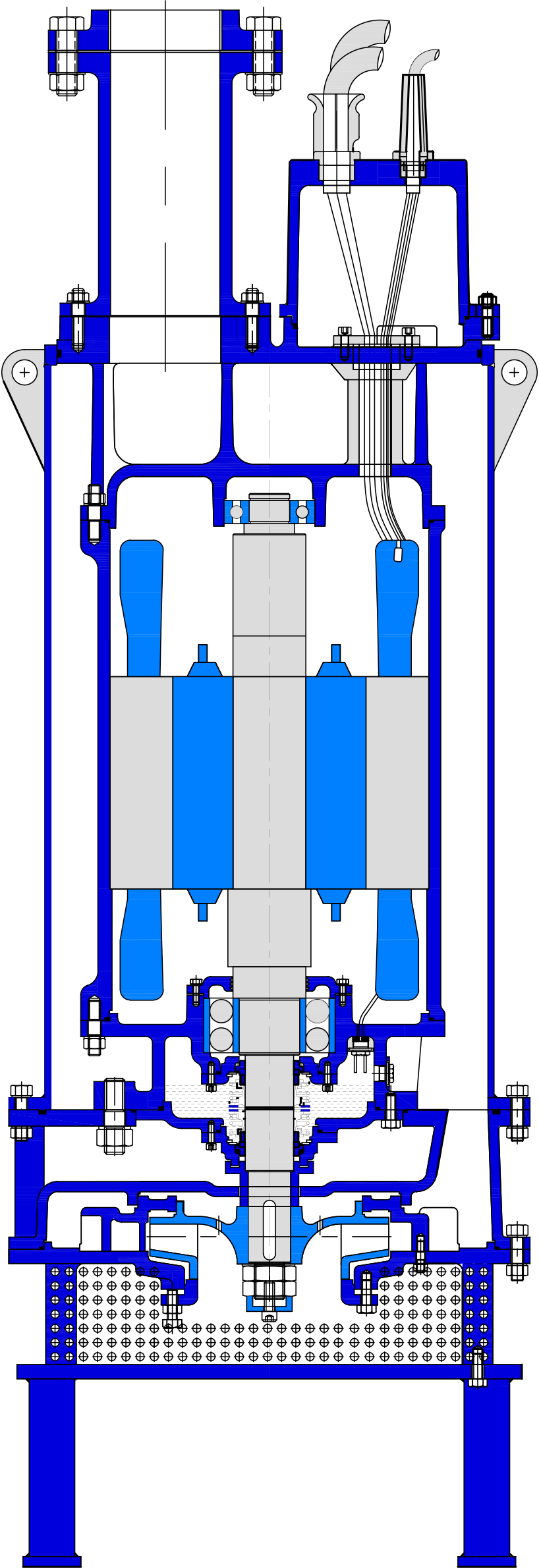

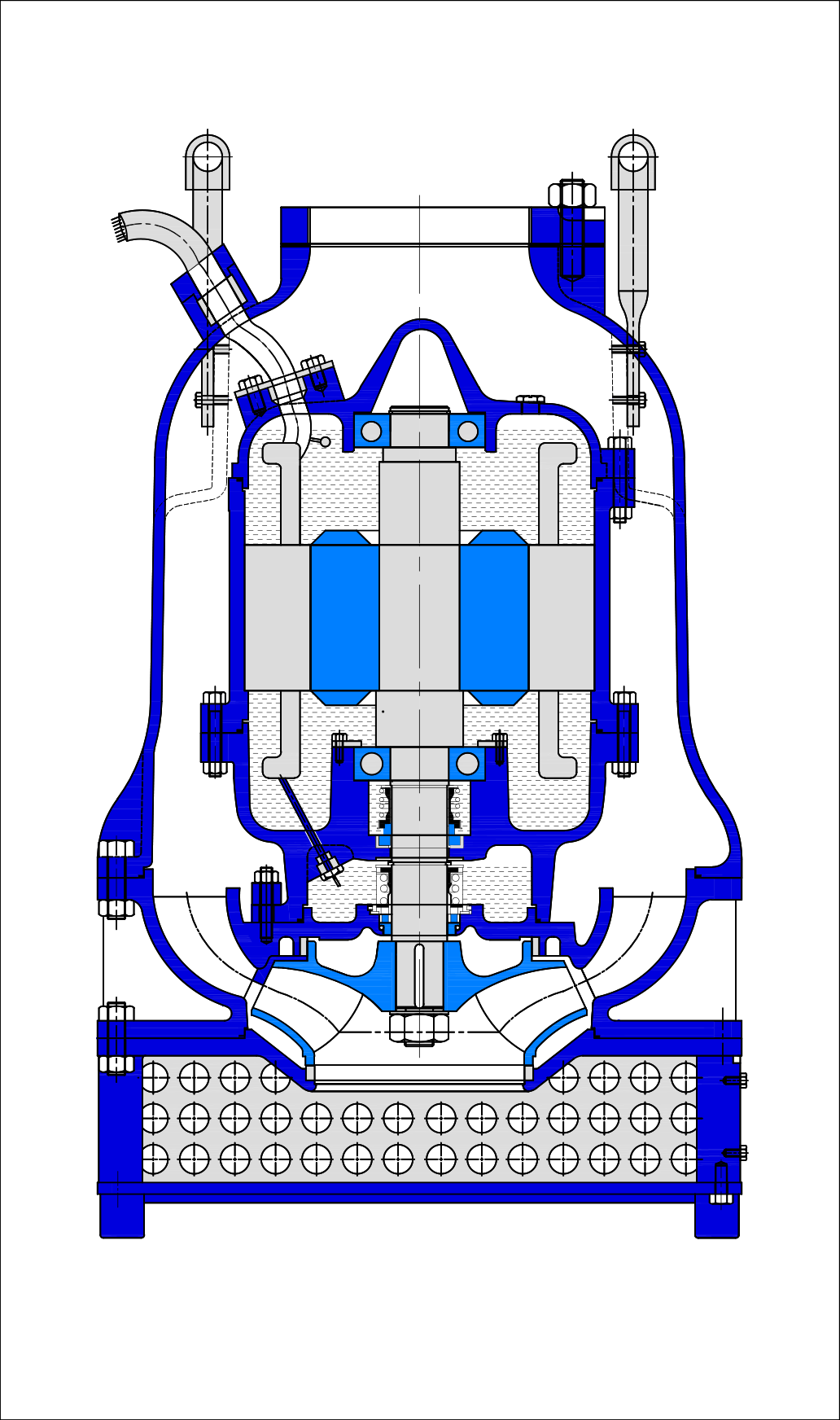

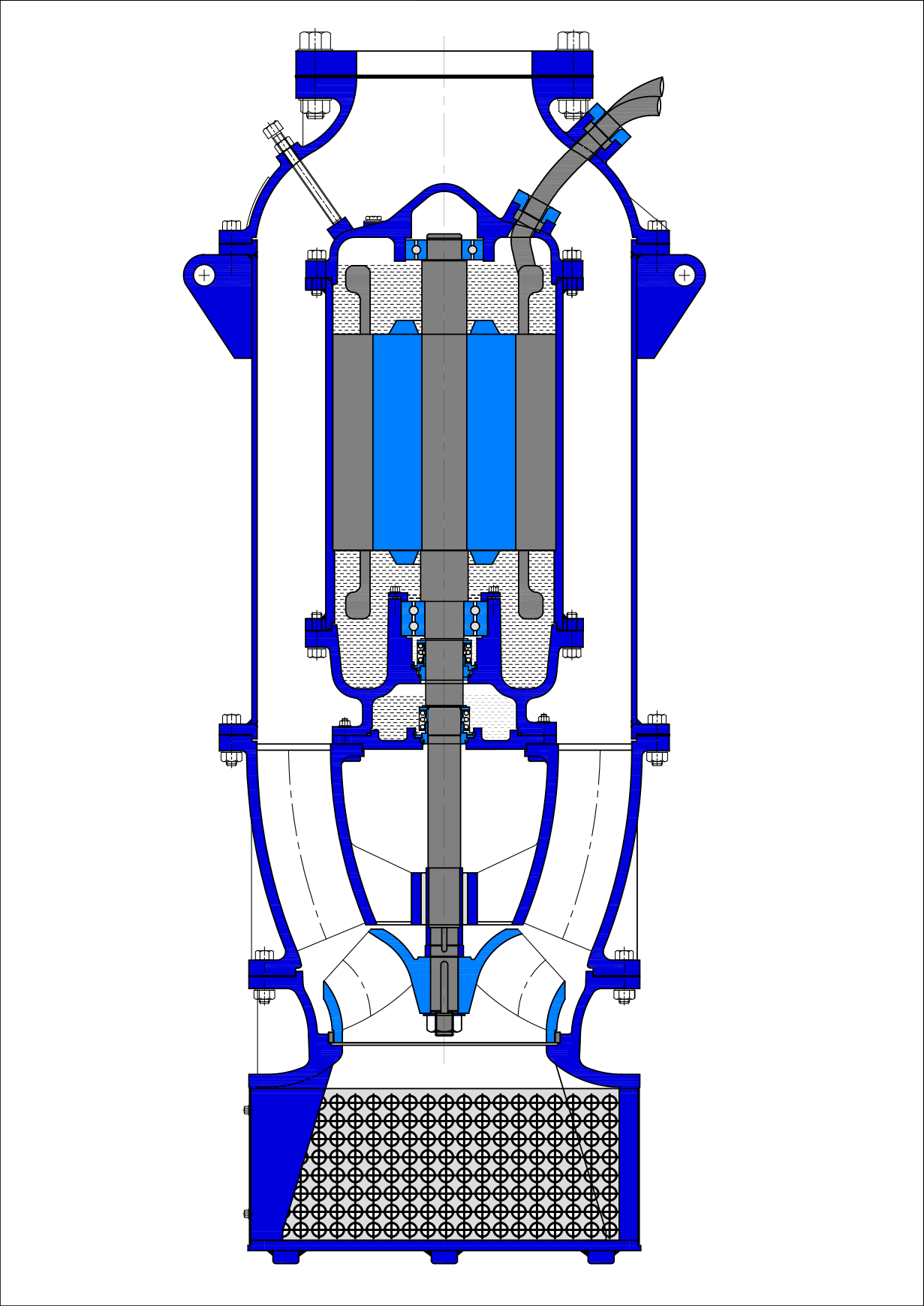

DJ Series Pumps

Features

| Inbuilt Controller – All DJC pumps between 3HP to 10HP are equipped with built-in protection against dry running, overload mechanical jamming etc. |

| Impeller – Wear Resistant SS Impeller with wide passages that can can pass solid up to 25mm. |

| Motor – Motor capable to withstand wide voltage fluctuations, Highly efficient dry motors with built-in protection against temperature rise. |

| Shaft – Extra heavy duty SS Shaft not expossed to pumpage liquid. |

| Efficiency Restoration System – Adjustable Neckring / Wear ring to restore efficiency. |

| Mechanical Seals – Dual mechanical seal, independent of discharge pressure, thus providing improved seal life. |

| Bearing – Heavy duty ball bearing used at top and bottom ends to balancer adverse load. |

| Seal -Guard Protection: Additional protection for Mechanical Seal by seal guard. |

| Cable Sealing – Special Leak proof cable sealing arrangement to avoid ingress of water through cable. No need to open motor for changing cable. |

| Moduler Design – Option of pump portion interchangability in given rating as per head/Flow requirement. |

| Cooling – Run-through cooling for better heat dissipation & low minimum submergence. |

Applications

- Basement Water Dewatering

- Storm Water Dewatering

- Pumping heavily contaminated water with Sand gravel and sludge at various construction sites.

- Sea Water Pumping

- Industrial Water Dewatering

- Dam Sites & Deep Excavation

- Micro Tunneling Projects

- Underground Civil Projects

DJ Series Pumps

| Tech. Specifications* | ||

| Rating | : | From 0.75 HP to 100 HP |

| RPM | : | 2900 (nominal) |

| Frequency | : | 50 HZ |

| Supply | : | Three phase- 415 V |

| Starting | : | DOL |

| Motor | : | Wet type / Dry type |

| Process Data | ||

| Liquid temperature | : | Max 40° C |

| Liquid Density | : | Max 1100 kg/m3 |

| Suitable for liquid pH | : | 6 to 8 |

| Stainer Hole Size | : | From 4 mm to 16 mm |

| Materials* | ||

| Impeller | : | CA – 15, CF8, CF8M |

| Shaft | : | AISI-410, SS-304, SS-316 |

| Difusser | : | Various grades of CI/ AL/ SS |

| Wear plate | : | Various grades of CI/ SS |

| Mech. Seal | Sic v/s Sic, Tc v/s Tc | |

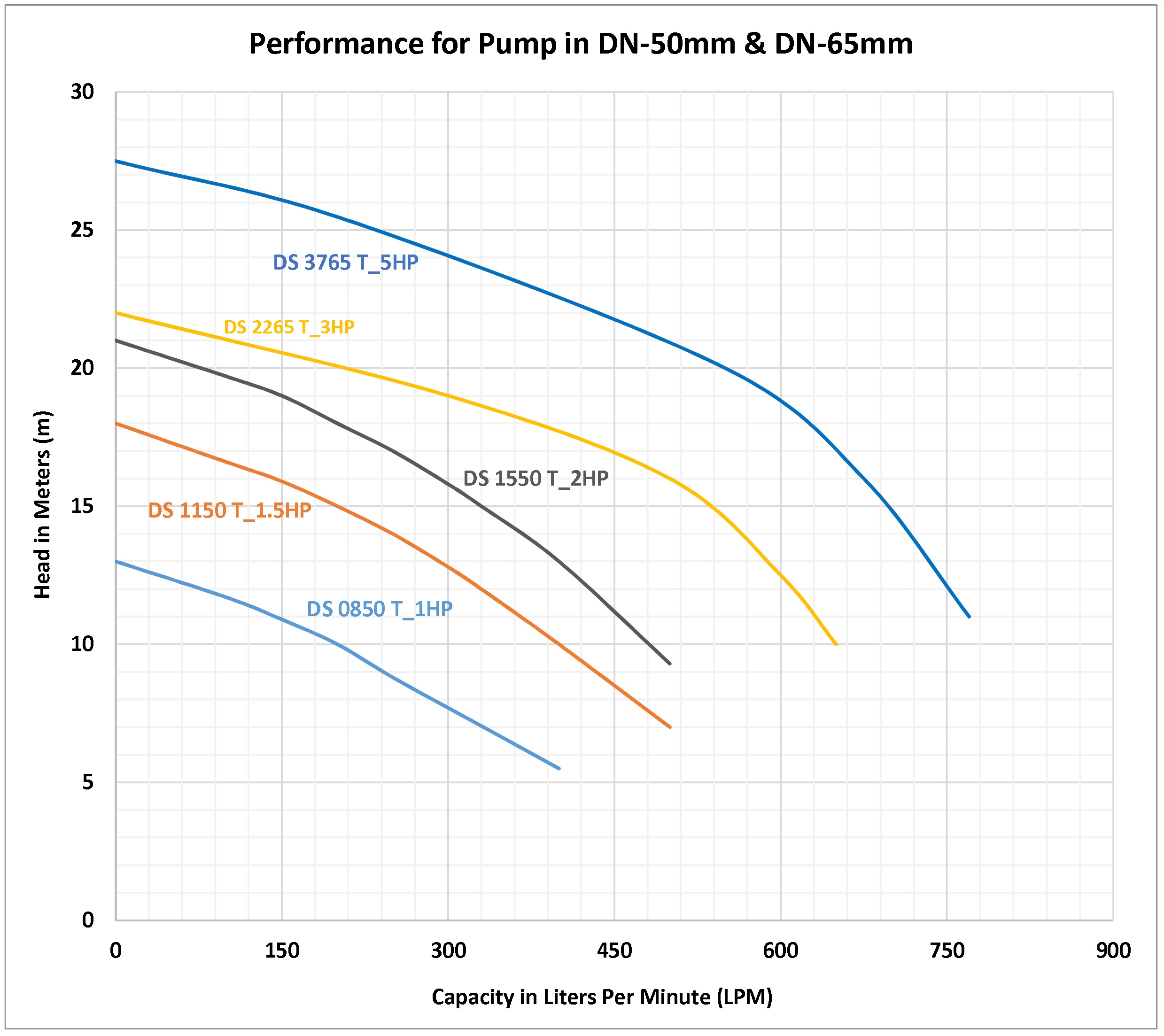

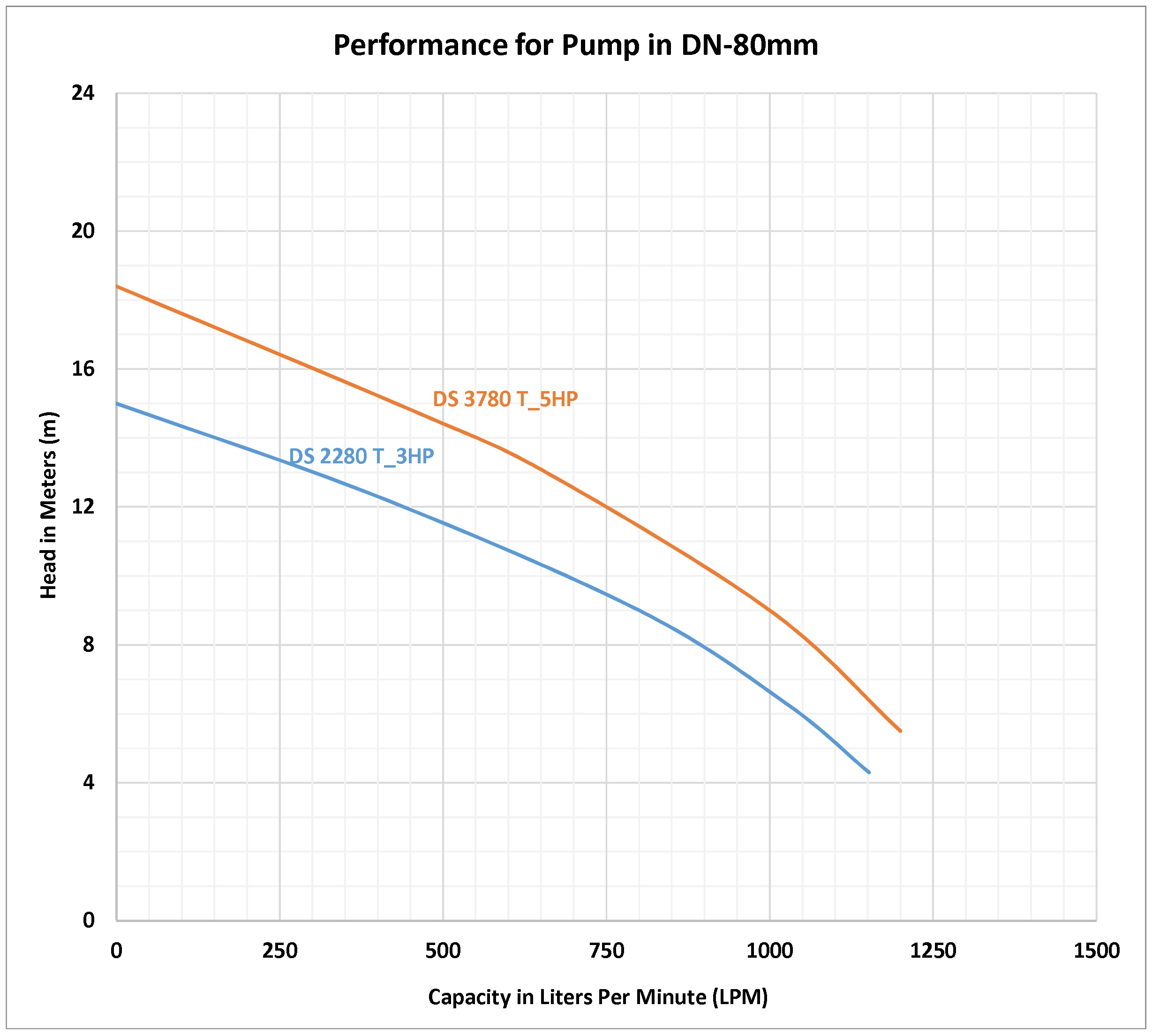

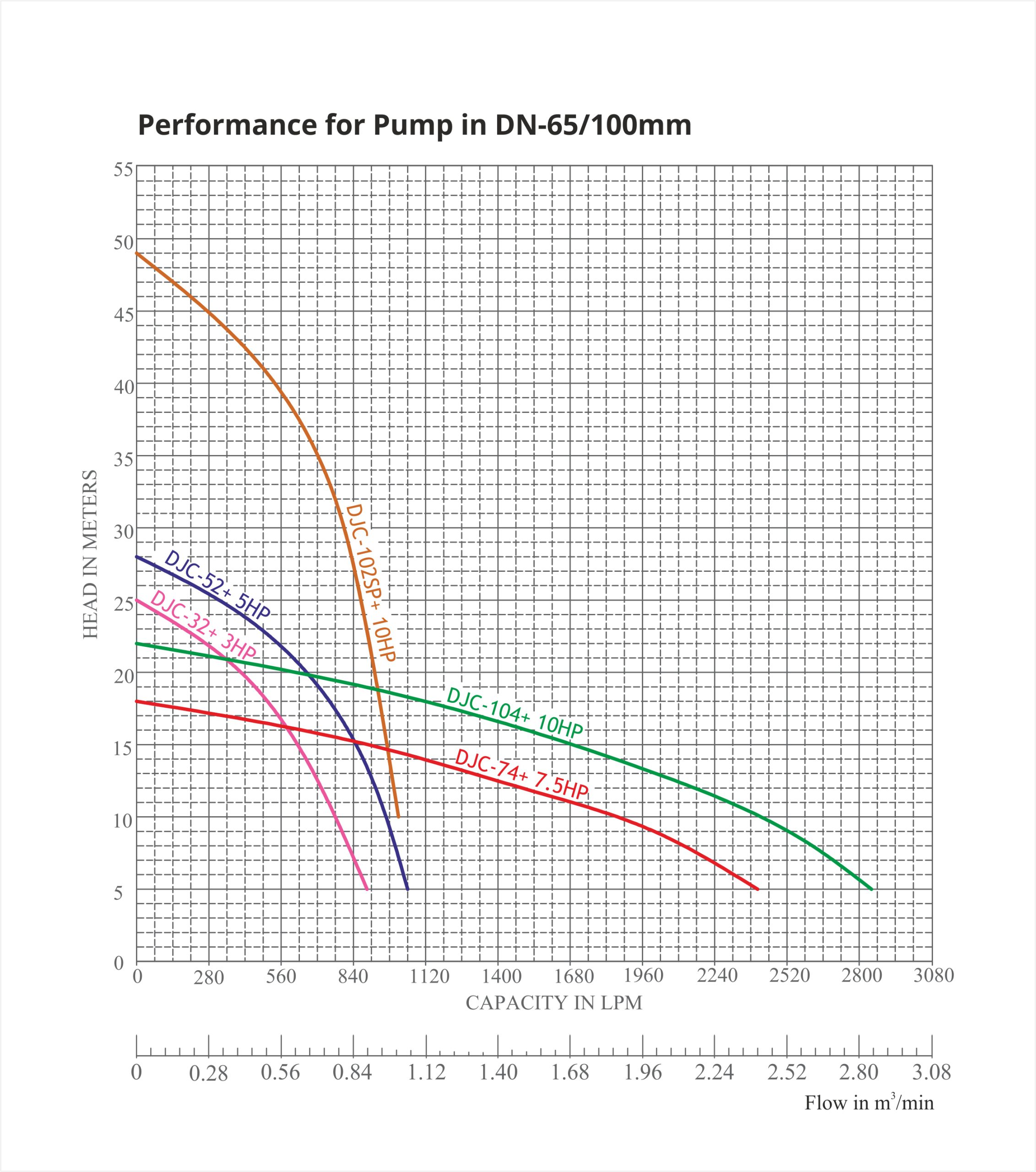

DJC Series Pumps

| Pump Model | HP/KW | RPM | OUTLET / DN SIZE | SOLID PASSAGE | MINIMUM SUBMERGENCE (Approx.) | WIDTH / OUTER DIA (Approx.) | HEIGHT (Approx.) | Net Weight (In Kg) (Approx.) |

|---|---|---|---|---|---|---|---|---|

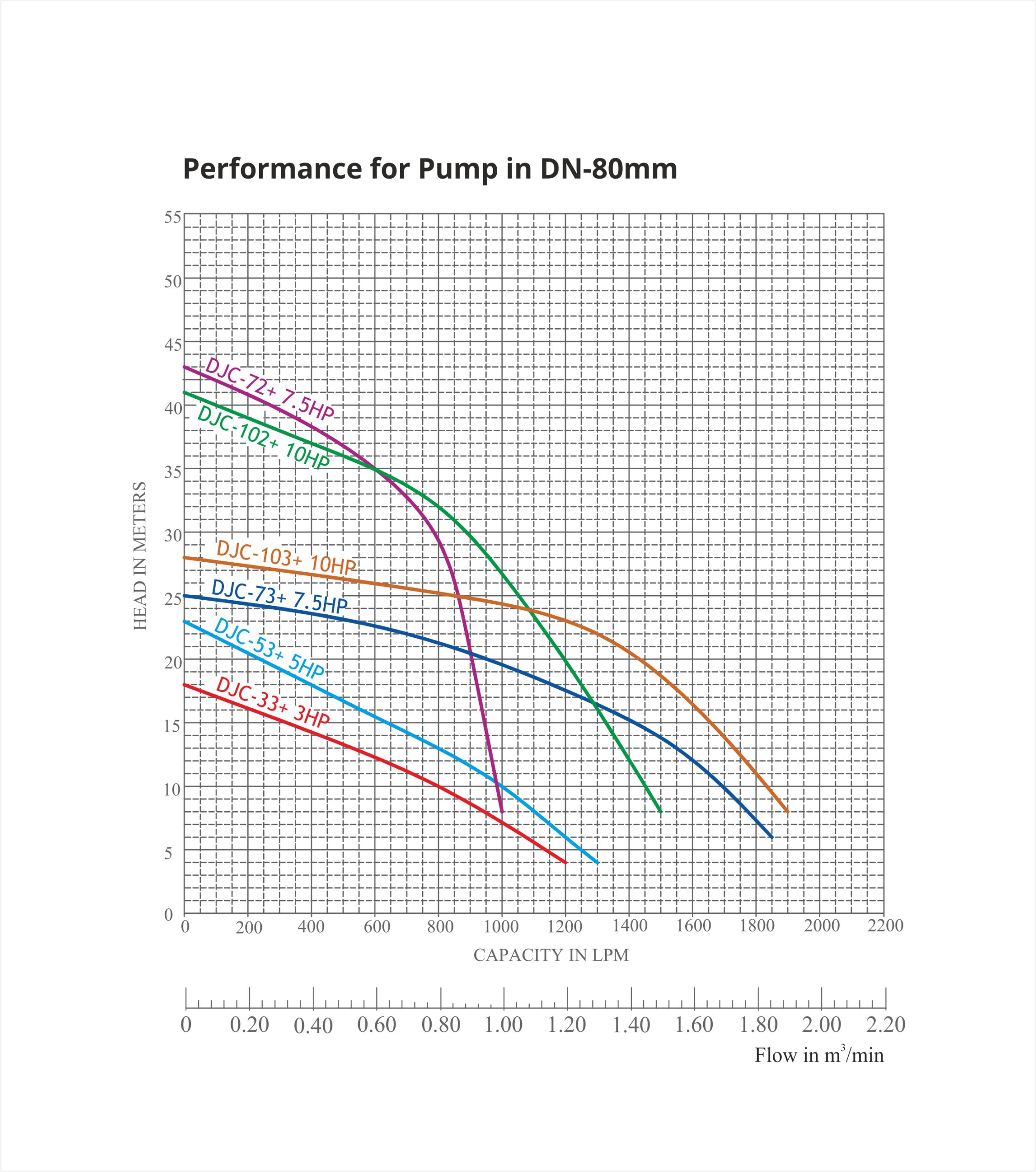

| DJC-32+ | 3.0/2.2 | 2900 | 65 | 8 | 100 | 270 | 722 | 47 |

| DJC-33+ | 3.0/2.2 | 2900 | 80 | 16 | 120 | 270 | 735 | 47 |

| DJC-52+ | 5.0/3.7 | 2900 | 65 | 8 | 100 | 270 | 722 | 49 |

| DJC-53+ | 5.0/3.7 | 2900 | 80 | 16 | 120 | 270 | 735 | 49 |

| DJC-72+ | 7.5/5.5 | 2900 | 80 | 8 | 110 | 270 | 770 | 62 |

| DJC-73+ | 7.5/5.5 | 2900 | 80 | 16 | 110 | 270 | 770 | 62 |

| DJC-74+ | 7.5/5.5 | 2900 | 100 | 16 | 150 | 340 | 808 | 70 |

| DJC-102+ | 10/7.5 | 2900 | 80 | 8 | 110 | 270 | 830 | 67 |

| DJC-102SP+ | 10/7.5 | 2900 | 65 | 8 | 110 | 270 | 830 | 67 |

| DJC-103+ | 10/7.5 | 2900 | 80 | 16 | 110 | 270 | 830 | 67 |

| DJC-104+ | 10/7.5 | 2900 | 100 | 16 | 150 | 340 | 870 | 80 |

| Note: All dimensions are in millimeter (mm). | ||||||||

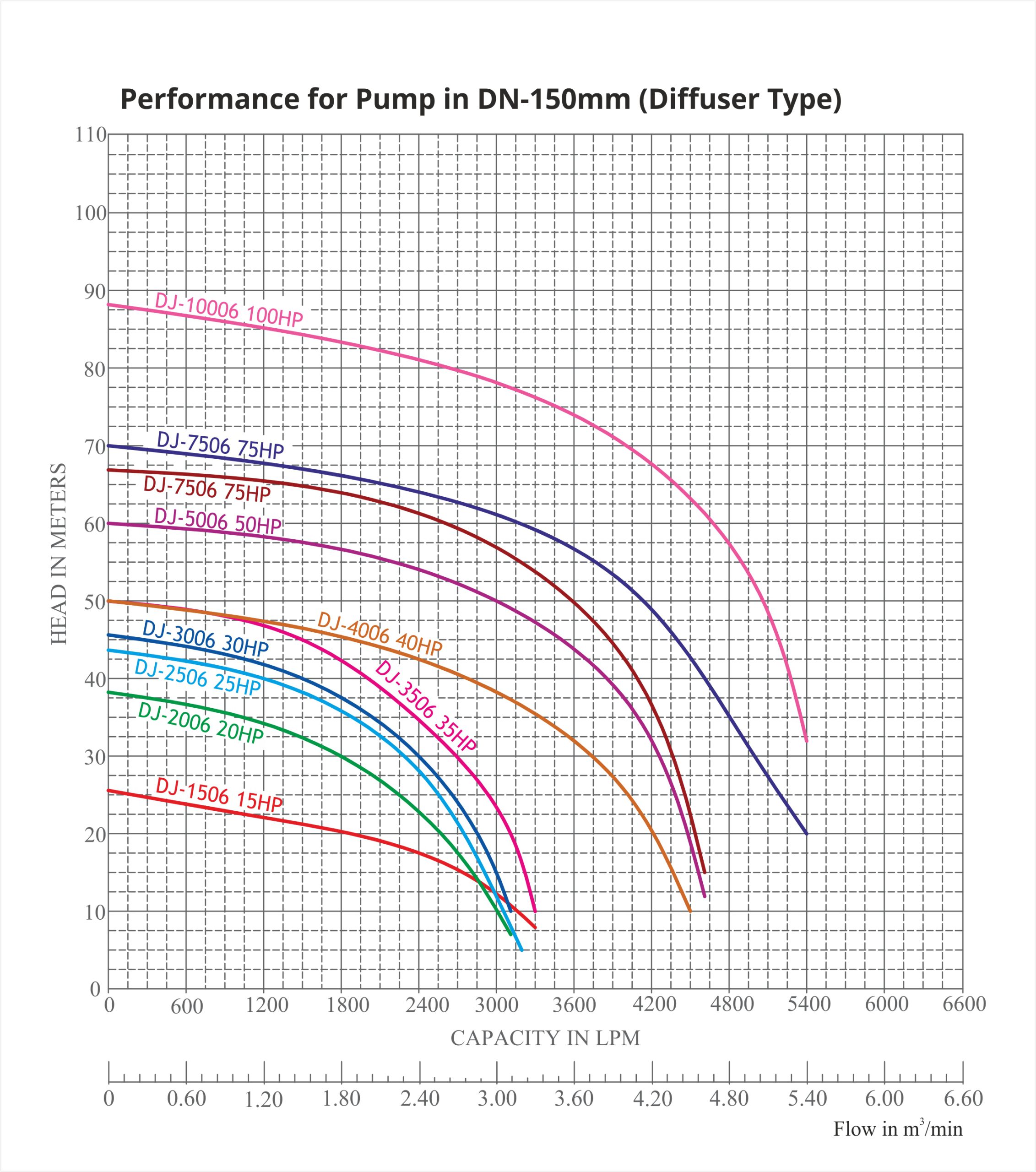

DJ Series Pumps

| Pump Model | HP/KW | RPM | OUTLET / DN SIZE | SOLID PASSAGE | MINIMUM SUBMERGENCE (Approx.) | WIDTH / OUTER DIA (Approx.) | HEIGHT (Approx.) | Net Weight (In Kg) (Approx.) |

|---|---|---|---|---|---|---|---|---|

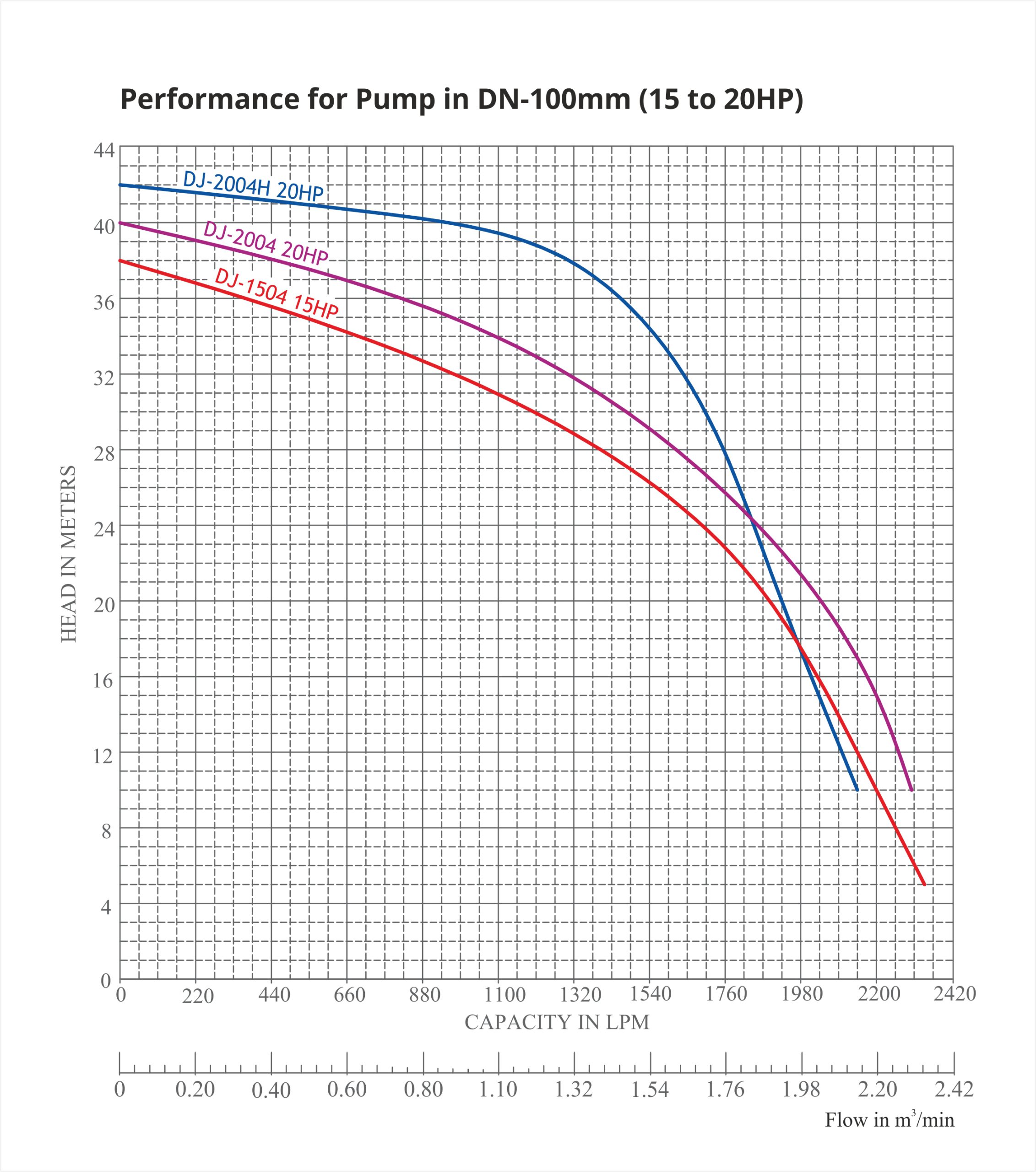

| DJ-1504 | 15/11 | 2930 | 100 | 8 | 180 | 390 | 1000 | 227 |

| DJ-1506 | 15/11 | 2920 | 150 | 16 | 180 | 435 | 1040 | 227 |

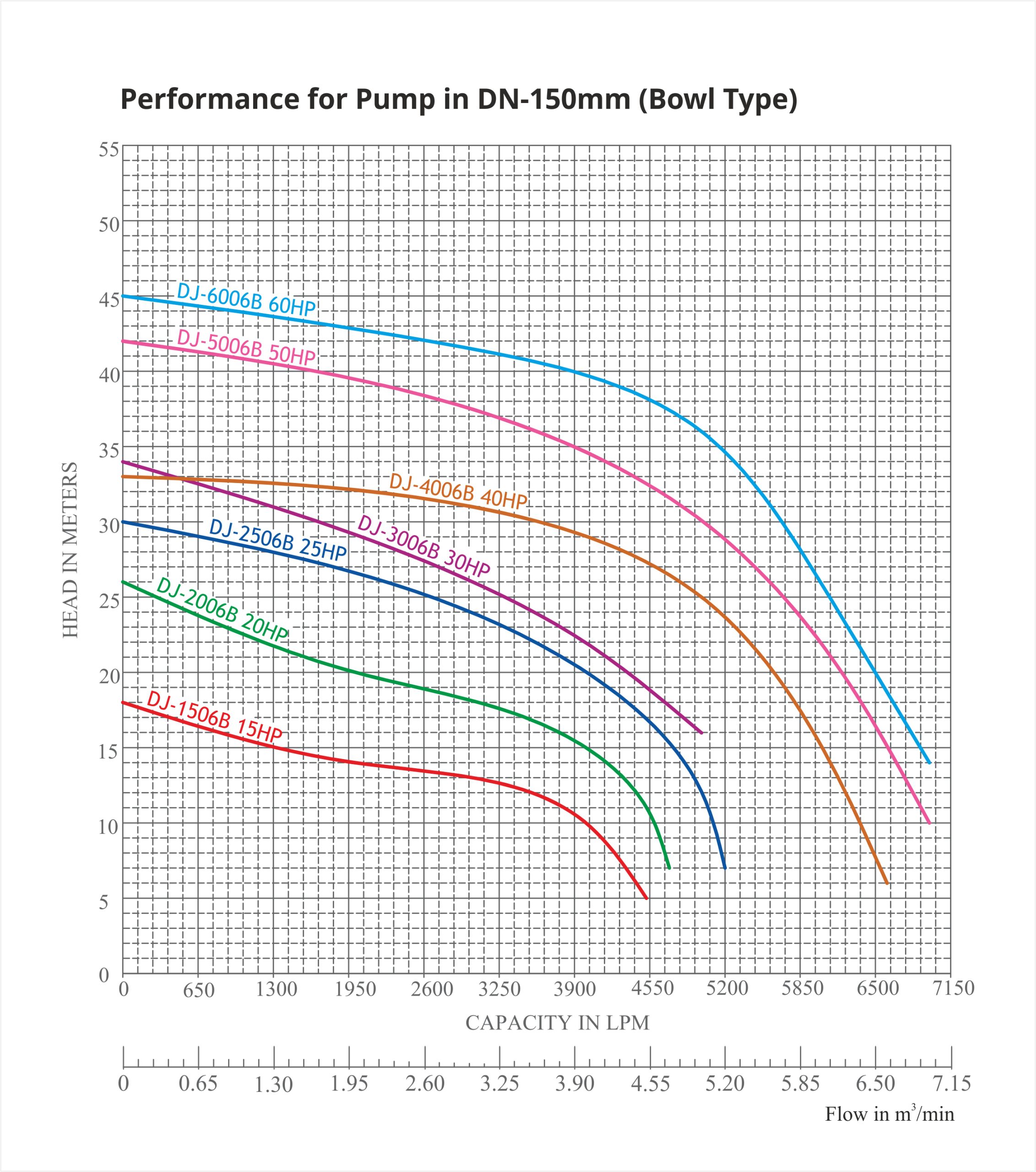

| DJ-1506B | 15/11 | 2920 | 150 | 16 | 200 | 435 | 1030 | 247 |

| DJ-2004 | 20/15 | 2930 | 100 | 8 | 180 | 390 | 1035 | 257 |

| DJ-2004H | 20/15 | 2880 | 100 | 8 | 180 | 390 | 1025 | 260 |

| DJ-2006 | 20/15 | 2930 | 150 | 16 | 180 | 435 | 1080 | 257 |

| DJ-2006B | 20/15 | 2930 | 150 | 16 | 200 | 435 | 1070 | 277 |

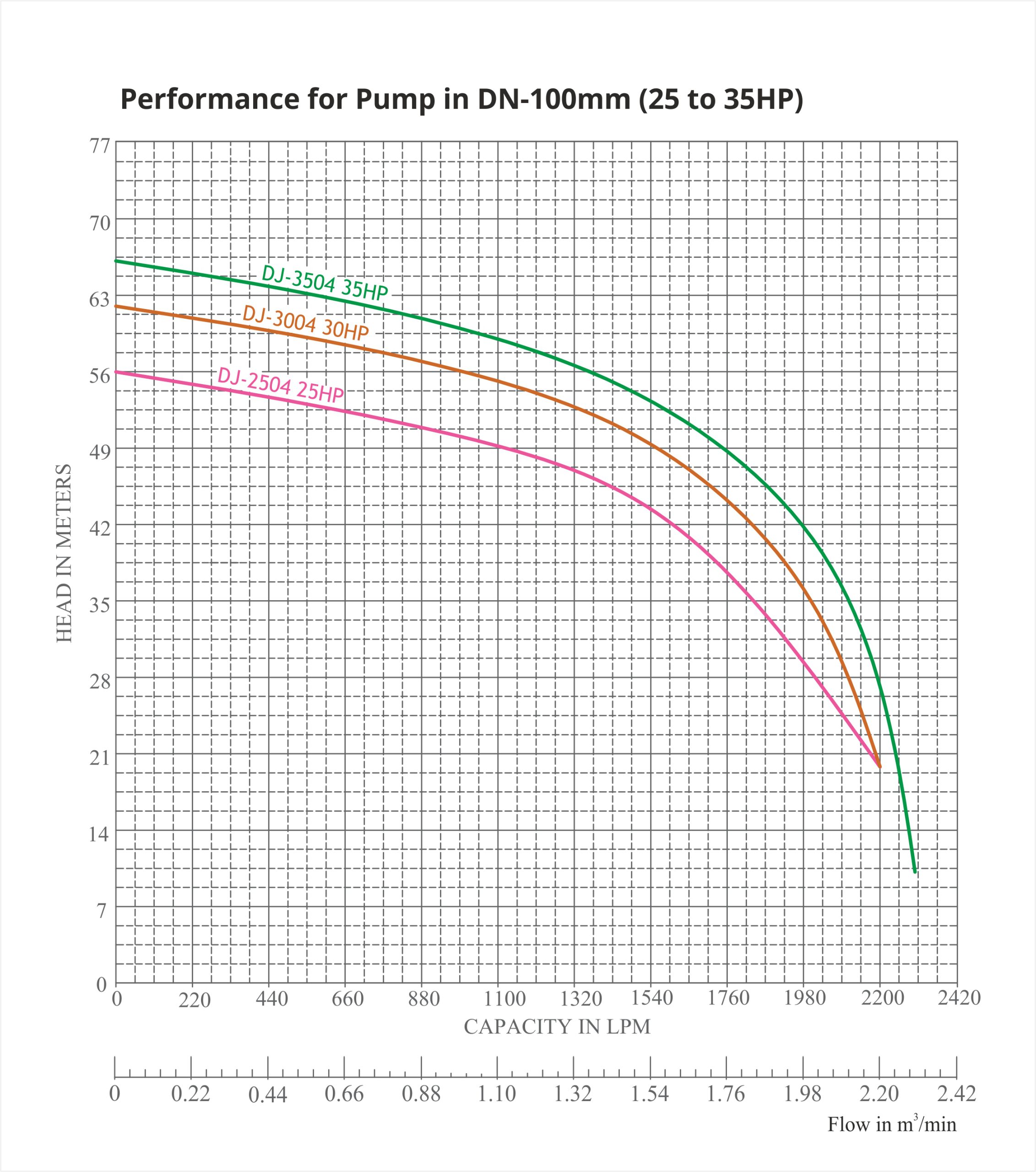

| DJ-2504 | 25/18.5 | 2930 | 100 | 8 | 180 | 390 | 1055 | 265 |

| DJ-2506 | 25/18.5 | 2930 | 150 | 16 | 180 | 435 | 1110 | 265 |

| DJ-2506B | 25/18.5 | 2930 | 150 | 16 | 200 | 525 | 1100 | 285 |

| DJ-3004 | 30/22 | 2930 | 100 | 8 | 180 | 390 | 1055 | 270 |

| DJ-3006 | 30/22 | 2930 | 150 | 16 | 180 | 435 | 1110 | 270 |

| DJ-3006B | 30/22 | 2930 | 150 | 16 | 200 | 525 | 1100 | 290 |

| DJ-3504 | 35/26.1 | 2935 | 100 | 8 | 180 | 390 | 1085 | 275 |

| DJ-3506 | 35/26.1 | 2935 | 150 | 16 | 180 | 435 | 1130 | 275 |

| DJ-4006 | 40/30 | 2900 | 150 | 16 | 340 | 545 | 1530 | 490 |

| DJ-4006B | 40/30 | 2955 | 150 | 16 | 1500 | 545 | 1560 | 490 |

| DJ-5006 | 50/37 | 2900 | 150 | 16 | 340 | 545 | 1585 | 522 |

| DJ-5006B | 50/37 | 2960 | 150 | 16 | 1500 | 545 | 1610 | 522 |

| DJ-6006 | 60/45 | 2900 | 150 | 16 | 340 | 545 | 1665 | 565 |

| DJ-6006B | 60/45 | 2960 | 150 | 16 | 1500 | 545 | 1695 | 565 |

| DJ-7506 | 75/55 | 2965 | 150 | 16 | 350 | 545 | 1750 | 650 |

| DJ-10006 | 100/75 | 2965 | 150 | 16 | 350 | 545 | 1790 | 730 |

| Note: All dimensions are in millimeter (mm). | ||||||||

DJ Series Pumps

Options

- DJC Pumps up to 10 HP can be offered with out Controller arrangement.

- Option of pump with dry motor as well as oil filled motor.

- Option of pumps with inbuilt agitator arrangement.

- Pumps can be offered for 60 Hz.

- Variety of MOCs to choose from.

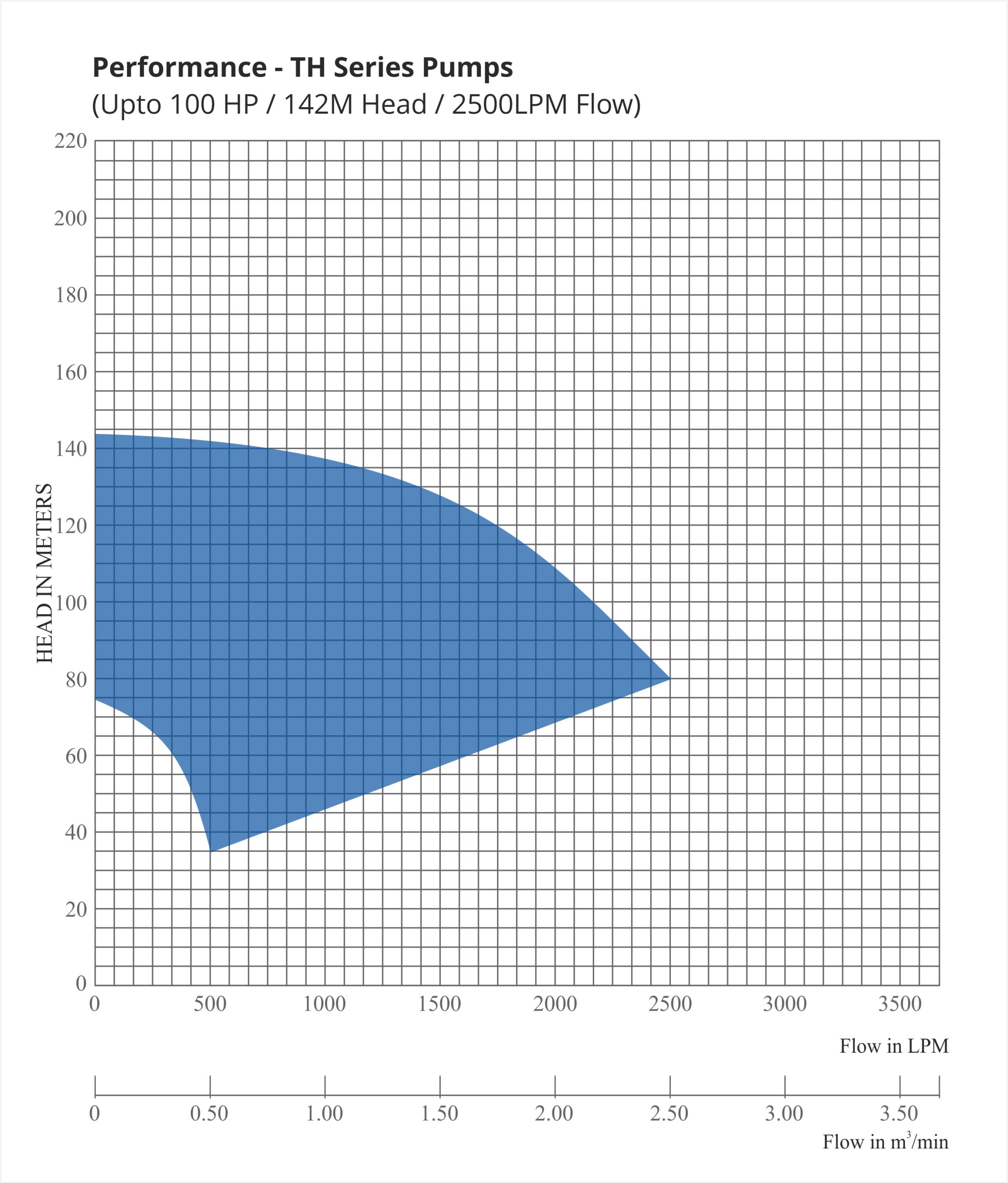

- Special series of pumps for pumping hot water

- Special series of pumps for saline water pumping

Recommendations

- Always flush the pump with clean water after use.

- In case maintenance always use Genuine spares.

- Ensure use of proper control panel for proper safety & running of Dewatering pumps.

- Always ensure that pump is properly earth.